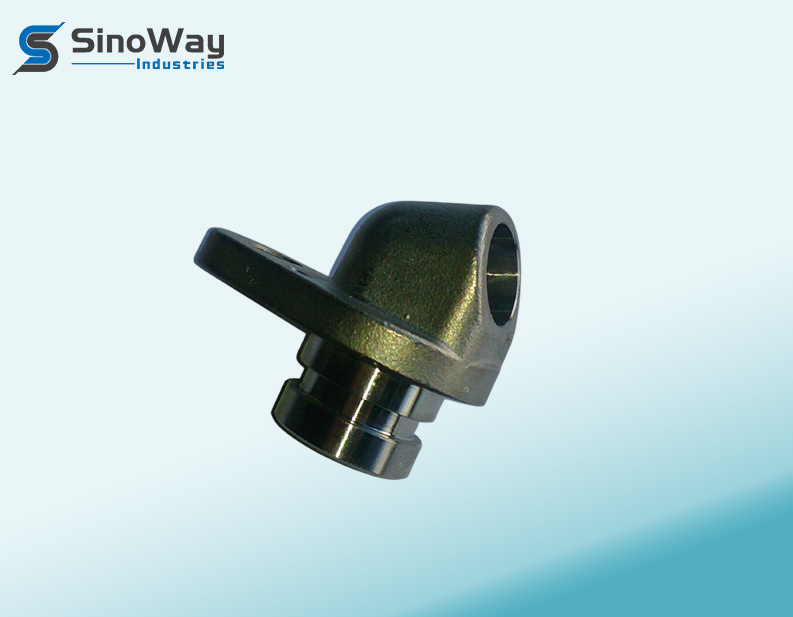

Casting Bearing Cover

Item No.: SWSAC0506

Material: Grey Iron

Main Manufacturing Process: Sand Casting

Surface: Painting

Application: Covering and Protecting the Bearings

Details of Products

Item No.

SWSAC0506

General Description

The casting bearing cover is used to protect the bearings from dust and such things. According to customers ‘ drawings, this kind of product is manufactured by Sand Casting Process, and usually, we use grey iron for this bearing cover.

Material

Grey Iron

Manufacturing Processes

Application

The main application of the bearing cover is to prevent dust during the usage of the bearings.

Manufacturing processes available with Sinoway

Based on the variety of capabilities of our factories, we can supply one-stop manufacturing processes, including

- Different kinds of sheet metal forming process

- Different kinds of metal casting processes

- Drop forging process

- Metal powder metallurgy process

- Kinds of Mechanical machining processes

- After-manufacturing processes include Welding processes, Surface finishing processes, and so on.

QC Policy

We have a strict quality control policy according to ISO9001, every product manufactured in our factories must get approved through at least three tests, including

- Raw materials inspection

- Pre-production samples inspection

- Production in-process inspection

- Final production inspection

- Packing & Delivery inspection

Our QC department can supply the inspection reports for each inspection they’ve made.

FAQ

Q: Do you sell this kind of product directly?

A: No, all of our products are custom manufactured for our clients, and what we supplied are OEM products only.

Q: What will you do if I have a request for similar products?

A: First of all, our engineers will evaluate the project and tell if it is suitable for us. They will discuss more details with you to know the project better, and then we will work out a reasonable manufacturing solution and its cost. And then submit it to you. After we agree on all the terms, we will start with a contract for molds and sample making, and then the mass production after samples get approved.

Q: How do you make out the qualified products for us?

A: After molds get ready, we will supply samples for your approval. And if there is any problem with the samples, we will modify the molds and re-make samples for your confirmation until the final qualified products get approved.

Q: What about the commercial terms?

A: For molding, we need 50%-50% payment. And while the mass production quantity reaches a certain number, these molding fees will be counted into your mass production payment.

For mass production orders, 30% of the total amount needs to be prepaid. And the balance needs to be cleared before the cargoes leading or against the copy of the shipment BL.

Q: What about the lead time?

A: It depends on the quantity and our production schedule. Generally speaking, for most of the products, molds could be finished within 30days. And the mass production order could be finished within 25-30days.

Q: What about the packaging?

A: The packaging method depends. Usually, cartons and plywood pallets are primary options. And other packaging methods like plywood boxes, steel pallets are also available.