Sinoway was established in 2011 and is a professional metal parts processing manufacturer. The products we have produced include powder metallurgy parts,sand casting parts,die casting parts,lost foam casting parts,deep drawing parts,shell mold casting parts,mechanical machining parts,lost wax investment casting parts,laser cutting parts, etc., which can be widely used in furniture fabrication,electrical appliances,construction fields,hardware,kinds of machinery,heavy equipment and other fields. The factories we cooperate with include two sheet metal manufacturing plants, three metal foundries and a forging plant. Our diverse metal product manufacturing capabilities can provide one-stop service for all your needs!

The company seizes opportunities, continuously innovates production processes, and strives to produce high-quality products. Our custom production lines include metal powder metallurgy lines,sheet metal fabricating lines,robot welding lines,metal parts machining lines,drop forging lines, etc. The company has various high-precision equipment, as well as a complete production management system, a group of experienced managers, an excellent design team, and skilled front-line employees. If you have any interest, please feel free to contact us.

The following table information is reference data about aluminum casting Stainless Steel Zinc Plating surface OEM,ODM,Custom Tolerance 0.01mm:

| Brand Name | Sinoway |

| Place of Origin | China |

| Type | metal parts |

| Condition | New |

| Sample | Availble |

| After-sale Service | Online technical support |

| MOQ | 15 pieces |

| OEM/ODM | Yes |

| Packing | cartons and plywood pallets |

| Application | automotive fabrication,furniture fabrication…etc |

| Port | Qingdao |

| Export Countries | Arabia,Kenya,Kazakhstan,Vietnam…etc |

| Factory visit | Welcomed Warmly |

| Payment | Paypal,T/T,Western Union…etc |

| Feature | high hardness,environment protection…etc |

| Sample | Provide Samples |

Please note: The above table data is for reference only. For specific information, please contact us.

For aluminum casting Stainless Steel Zinc Plating surface OEM,ODM,Custom Tolerance 0.01mm, our quality management policy includes the following aspects:

Inspection of raw material procurement and the quality;

Prototypes & Pre-Production quality inspection;

Pre-production sample quality inspection;

Sampling inspection during the production process;

Quality inspection after mass production;

Packaging and transportation inspection;

All tests must have traceable inspection reports on file.

How To Work With Us?

Phase 1

Send us the design or manufacturing drawings for evaluation. Both 2D and 3D files are acceptable.

Phase 2

Discuss the metal parts’ manufacturability and interchangeability to fix the final design.

Phase 3

Make the quote, confirm the order, and start tooling, modeling, and mass production.

Phase 4

Inspect the cargoes, package up, and arrange the delivery to you.

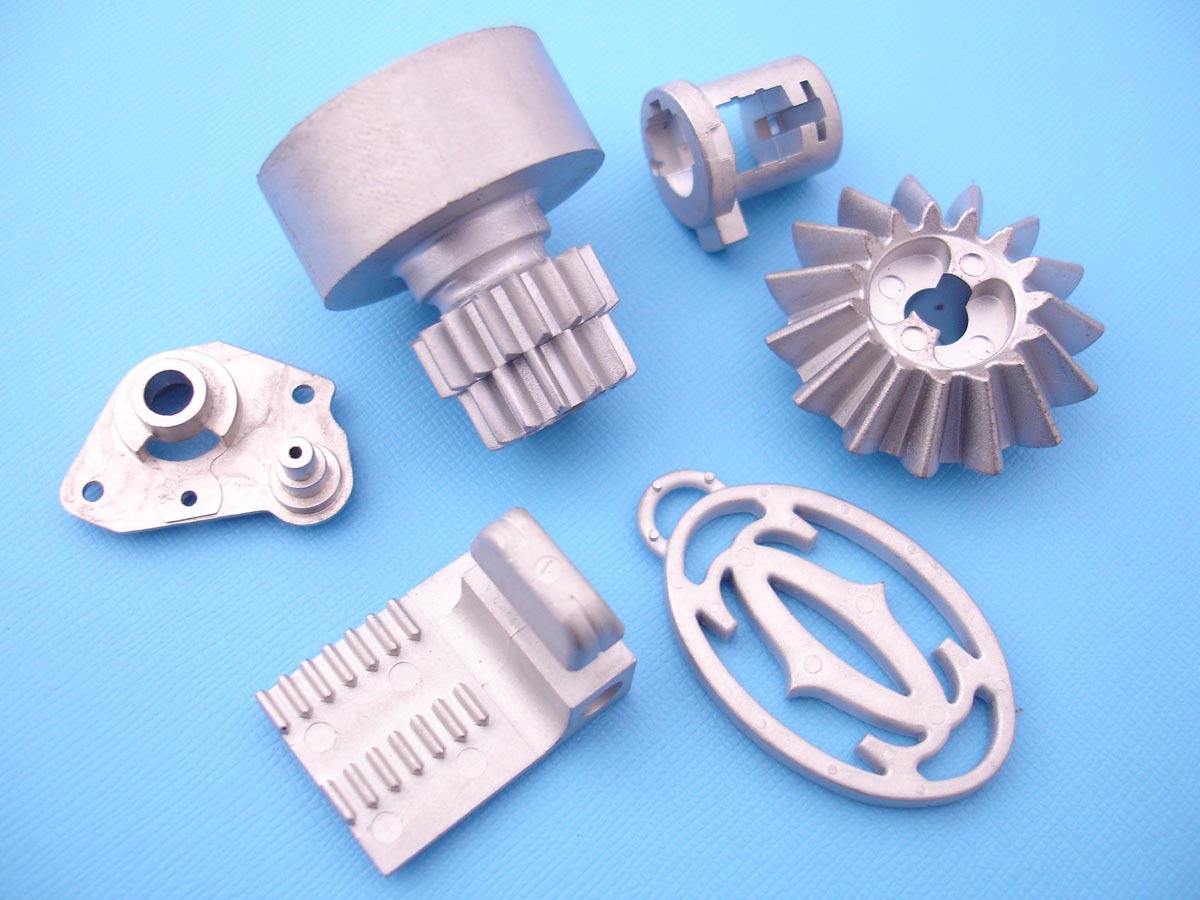

Some of our products

This is our workshop

This is our factory

Booth at the exhibition