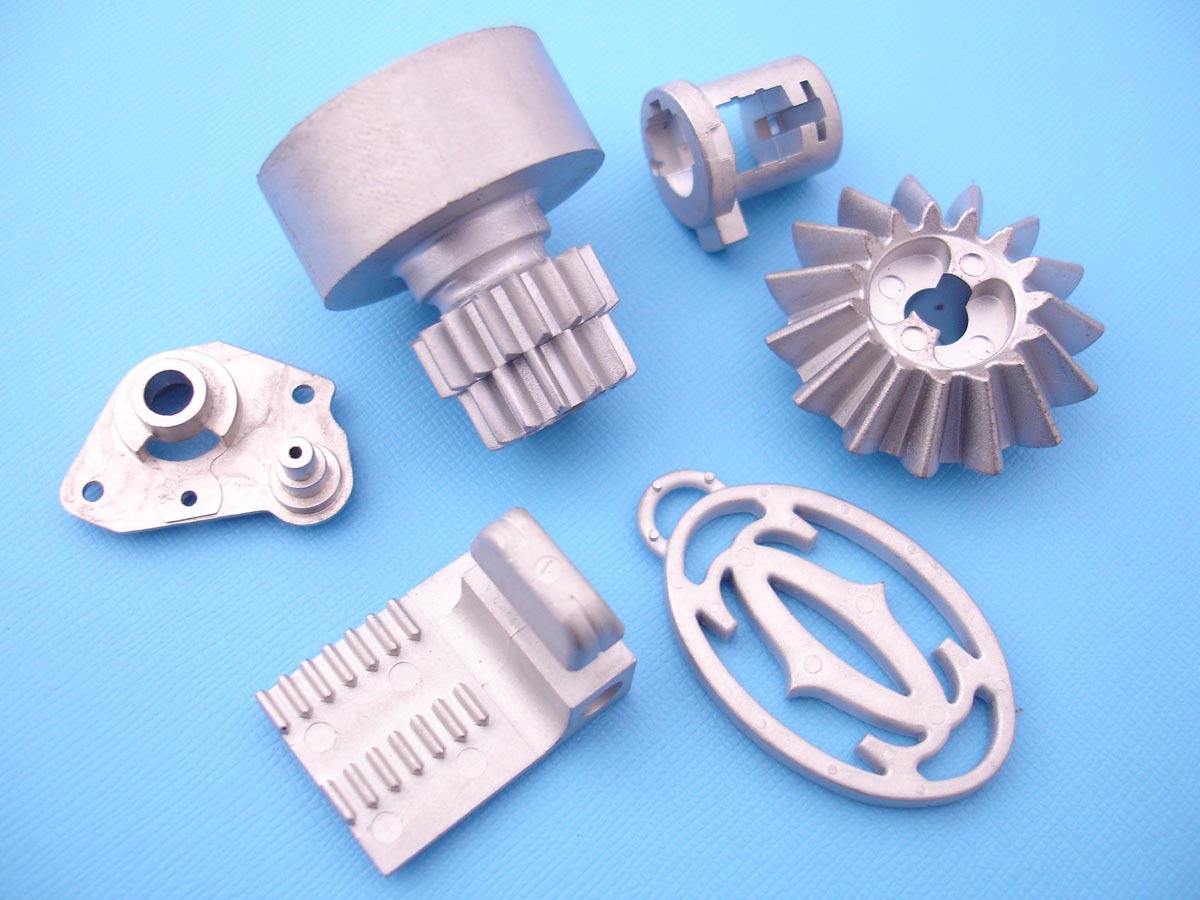

In the world of manufacturing, aluminum casting plays a crucial role across multiple industries due to its lightweight, high corrosion resistance, and versatile properties. However, when it comes to maximizing the strength and performance of aluminum castings, heat treatment is an essential step. At Sinoway, a leading sheet metal manufacturer, we specialize in providing top-quality heat treatment solutions for aluminum casting to meet the demands of various industrial applications, from automotive to aerospace and beyond.

In this article, we’ll explore the importance of heat treatment for aluminum castings, the various methods used, and how Sinoway delivers high-performance aluminum casting solutions for clients around the world.

What is Heat Treatment for Aluminum Castings?

Heat treatment is a process used to alter the physical and sometimes chemical properties of a material to enhance its performance characteristics. In aluminum castings, heat treatment is essential to increase strength, hardness, ductility, and resistance to wear and corrosion. By carefully controlling the heating and cooling cycles, aluminum alloys undergo transformations that improve their internal structure, making them more suitable for demanding applications.

Key Benefits of Heat-Treated Aluminum Castings

- Increased Strength: Aluminum’s tensile strength can be significantly enhanced through heat treatment, enabling it to withstand higher loads and stresses.

- Enhanced Ductility: Heat treatment improves the ductility of aluminum, making it more flexible and resistant to cracking under stress.

- Improved Corrosion Resistance: Heat treatment can reduce impurities and refine the alloy’s microstructure, increasing its resistance to corrosion.

- Better Machinability: Treated aluminum castings are easier to work with, improving productivity and reducing tool wear in machining operations.

- Extended Service Life: Components made from heat-treated aluminum are more durable, providing greater longevity and reliability in demanding environments.

Common Heat Treatment Processes for Aluminum Casting

There are several heat treatment techniques used to improve the properties of aluminum castings, each serving a unique purpose. Sinoway employs various heat treatment methods based on the specific requirements of our clients.

1. Solution Heat Treatment

Solution heat treatment involves heating the aluminum casting to a high temperature (around 950°F to 1050°F) and holding it at that temperature to allow alloying elements, such as copper or magnesium, to dissolve uniformly. After the solutionizing phase, the material is rapidly quenched in water to trap the dissolved elements in place, creating a supersaturated solid solution.

Benefits of Solution Heat Treatment:

- Significantly increases the tensile and yield strength of aluminum.

- Enhances the ductility and toughness of the casting.

- Ideal for parts requiring high strength and impact resistance.

At Sinoway, our solution heat treatment process is optimized to ensure uniform temperature distribution and precise quenching to prevent distortion or cracking, resulting in highly resilient aluminum castings.

2. Aging (Precipitation Hardening)

After solution heat treatment, aluminum castings can undergo an aging process, also known as precipitation hardening. Aging involves heating the casting to a moderate temperature (typically between 250°F to 400°F) to allow precipitates to form within the alloy structure. These precipitates enhance the hardness and strength of the casting by blocking dislocation movement.

Types of Aging:

- Natural Aging: Occurs at room temperature and is suitable for alloys that gain hardness over time.

- Artificial Aging: Performed at elevated temperatures to speed up the hardening process and achieve specific mechanical properties.

At Sinoway, we use controlled aging techniques to achieve optimal hardness and strength, ensuring that each aluminum casting is tailored to meet precise application requirements.

3. Annealing

Annealing is a heat treatment process used to soften aluminum castings by relieving internal stresses and improving ductility. In this process, the casting is heated to a specified temperature (around 600°F to 750°F) and then cooled slowly. Annealing can be useful in castings that require additional machining or forming after casting, as it makes the aluminum easier to work with.

Benefits of Annealing:

- Reduces hardness and increases ductility for easier machining.

- Relieves internal stresses caused by casting or previous heat treatments.

- Suitable for components that need to undergo forming or bending processes.

Sinoway employs precise annealing techniques to ensure the stability and quality of aluminum castings, providing components that are easier to process without sacrificing performance.

4. Stress Relief Heat Treatment

Stress relief is a low-temperature heat treatment (around 300°F to 400°F) used to remove residual stresses from the casting process. Aluminum castings can develop internal stresses during solidification or rapid cooling, leading to potential warping or cracking. Stress relief minimizes these risks, ensuring dimensional stability and longevity.

Benefits of Stress Relief Heat Treatment:

- Minimizes risk of distortion during machining.

- Enhances dimensional stability of the casting.

- Improves resistance to stress-related failures.

Sinoway’s stress relief process ensures that our aluminum castings remain stable and robust, ideal for components requiring high dimensional accuracy.

5. T6 and T7 Heat Treatment for Aluminum Castings

Two popular heat treatment conditions for aluminum castings are T6 and T7, each offering unique advantages based on the end use.

- T6 Treatment: This process involves solution heat treatment followed by artificial aging. T6-treated aluminum castings provide excellent strength and hardness, making them suitable for high-stress applications like automotive parts and aerospace components.

- T7 Treatment: In this treatment, aluminum castings undergo an extended aging process, producing a slightly lower strength but higher ductility than T6. This makes T7 ideal for applications where impact resistance and flexibility are more critical than ultimate strength.

Sinoway customizes T6 and T7 treatments for each casting, ensuring that our clients receive parts that meet the precise demands of their industries.

Applications of Heat-Treated Aluminum Castings

Heat-treated aluminum castings are used across various industries where high strength, lightweight properties, and corrosion resistance are essential. Here are some common applications:

Automotive Industry

In automotive manufacturing, heat-treated aluminum castings are used for components like engine blocks, cylinder heads, suspension parts, and transmission housings. The high strength and durability of treated aluminum make it an ideal choice for reducing vehicle weight without compromising safety or performance.

Aerospace Industry

For aerospace applications, aluminum castings must meet strict requirements for strength-to-weight ratio and corrosion resistance. Heat-treated aluminum is commonly used in components such as landing gear, engine mounts, and structural supports where lightweight durability is crucial.

Industrial Equipment

Heat-treated aluminum castings are utilized in heavy machinery and industrial equipment where components are exposed to high mechanical stress and temperature variations. Parts like pump housings, valve bodies, and compressor blades benefit from the enhanced properties provided by heat treatment.

Electrical and Electronic Applications

In electronics, aluminum castings are often used for heat sinks and enclosures due to their excellent thermal conductivity and corrosion resistance. Heat-treated aluminum castings offer improved thermal management, helping electronic components maintain optimal performance.

Why Choose Sinoway for Heat-Treated Aluminum Castings?

At Sinoway, we are committed to delivering high-quality, heat-treated aluminum casting solutions designed to meet the unique needs of each client. Our expertise in sheet metal manufacturing and precision casting, combined with state-of-the-art heat treatment processes, ensures that every component meets the highest standards of performance, durability, and precision.

Here’s what sets Sinoway apart:

- Advanced Heat Treatment Technology: We use cutting-edge equipment and techniques to perform precise heat treatments, ensuring consistent quality and optimal performance.

- Customization: Our team works closely with clients to tailor each casting to their specific needs, from alloy selection to heat treatment specifications.

- Quality Assurance: Every product undergoes rigorous quality checks, including dimensional accuracy and mechanical property testing, to guarantee reliability and safety.

- Timely Delivery: Our streamlined manufacturing and supply chain management ensure that our products reach clients on time, supporting efficient production schedules.

Conclusion

Heat treatment is an essential step in enhancing the strength, performance, and durability of aluminum castings. With advanced heat treatment processes like solution treatment, aging, annealing, stress relief, and specialized T6/T7 treatments, Sinoway delivers high-performance aluminum casting solutions that meet the needs of demanding industries.

For reliable and customized heat-treated aluminum castings, trust Sinoway. Contact us today to discuss how we can help you optimize your aluminum components for maximum strength, longevity, and cost-efficiency.