In today’s competitive manufacturing environment, finding the right sheet metal processing service provider is critical for ensuring the quality, durability, and cost-efficiency of your products. Whether you’re in the automotive, aerospace, electronics, or construction industry, the precision and reliability of your sheet metal components can significantly impact your business operations. One of the leading names in this domain is Sinoway, a trusted sheet metal manufacturer renowned for its state-of-the-art technology, skilled workforce, and commitment to delivering exceptional quality.

However, with numerous options available in the market, selecting the best sheet metal processing service provider can feel overwhelming. To help you make an informed decision, this comprehensive guide will discuss the critical factors to consider when choosing a partner like Sinoway for your sheet metal manufacturing needs.

Understanding Your Business Needs

Before diving into the selection process, it’s essential to have a clear understanding of your business requirements. This includes the type of sheet metal components you need, the volume of production, and the specific industry standards your products must meet. Here’s how you can evaluate your needs:

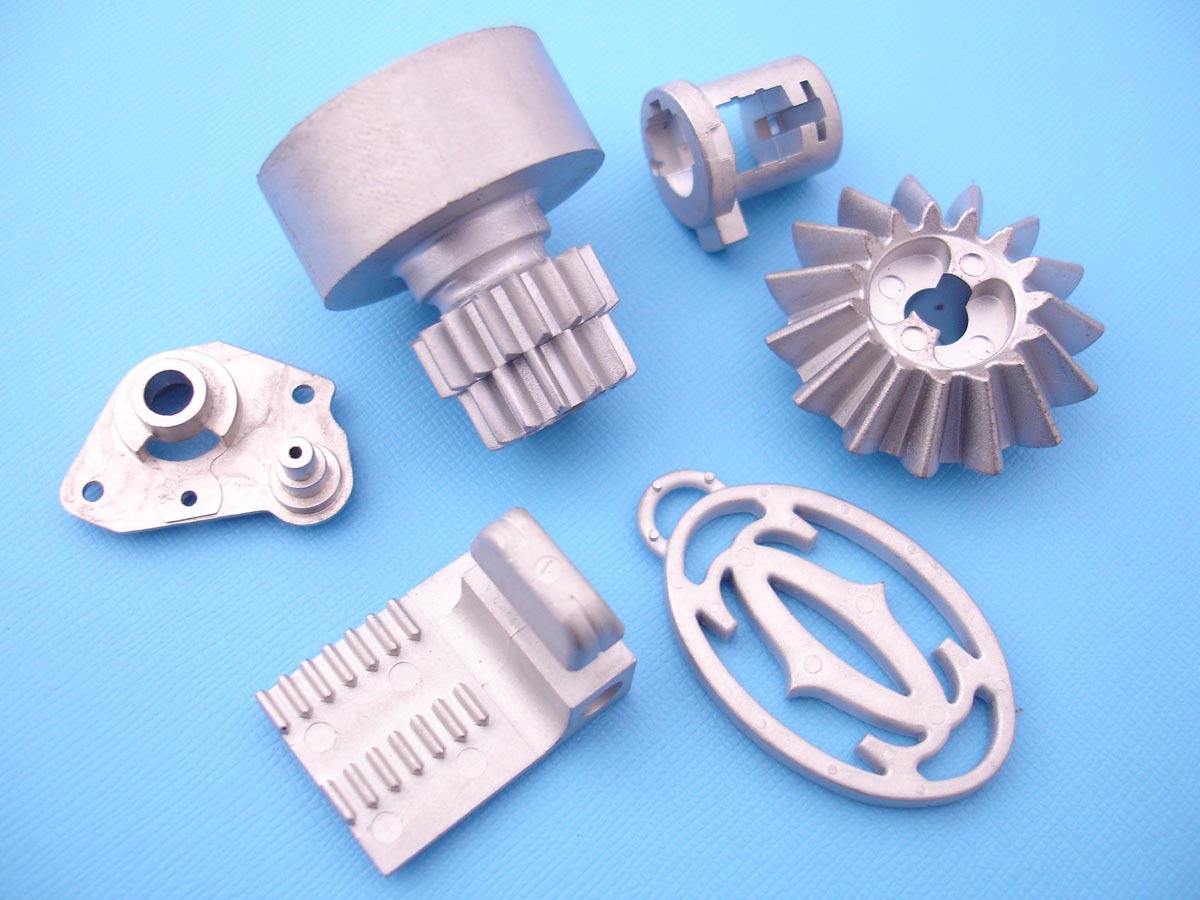

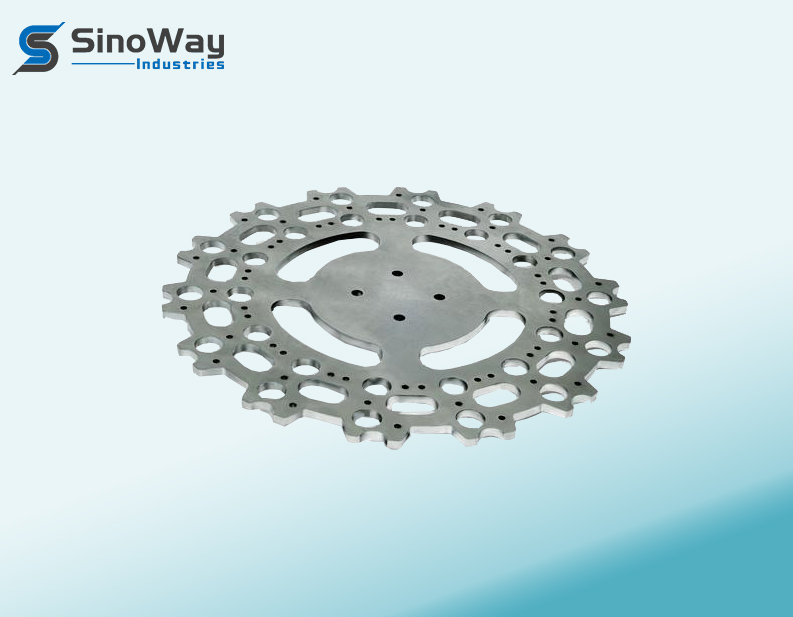

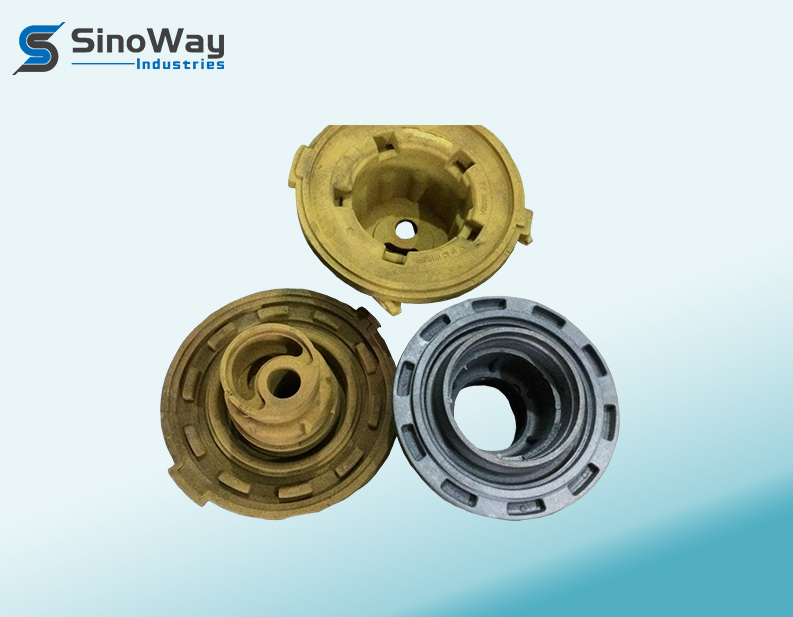

die casting products category

album bookstands

sintered gears

lost foam casting parts

z shape brackets

metal castingdie casting

- Product Specifications: Determine the dimensions, material type, and tolerances required for your sheet metal parts.

- Production Volume: Identify whether you need low-volume, high-mix production or high-volume, low-mix production.

- Industry Standards: Ensure your components comply with relevant certifications and standards, such as ISO, RoHS, or CE.

- Budget Constraints: Define your budget to balance cost-efficiency with quality.

Once you have a clear picture of your needs, you can better evaluate potential service providers like Sinoway to ensure they align with your business goals.

Why Choose Sinoway for Sheet Metal Processing?

Sinoway has established itself as a leading sheet metal manufacturer by consistently delivering high-quality products and services. Here are some reasons why Sinoway is a preferred choice for businesses worldwide:

1. Advanced Technology and Equipment

Sinoway utilizes cutting-edge machinery and technology to ensure precision and efficiency in its sheet metal processing operations. From laser cutting and CNC machining to bending and welding, their equipment is designed to handle a wide range of applications with minimal errors.

2. Skilled Workforce

The company boasts a team of highly skilled engineers and technicians who bring years of experience to the table. Their expertise ensures that every project is executed with the highest level of accuracy and attention to detail.

3. Customization Capabilities

Sinoway understands that every business has unique requirements. They offer tailored solutions to meet specific client needs, whether it’s a custom design, unique material, or specialized finishing process.

4. Commitment to Quality

Quality is at the core of Sinoway’s operations. The company follows stringent quality control measures at every stage of production to ensure that the final product meets or exceeds customer expectations.

5. Competitive Pricing

Despite their premium services, Sinoway offers competitive pricing to provide value for money. Their cost-effective solutions make them an ideal choice for businesses of all sizes.

Factors to Consider When Choosing a Sheet Metal Manufacturer

While Sinoway is an excellent option, it’s essential to evaluate any sheet metal processing service provider against specific criteria. Here are the key factors to consider:

1. Experience and Reputation

Look for a company with a proven track record in the industry. Check client testimonials, case studies, and reviews to gauge their reputation. Sinoway, for instance, has years of experience and a strong portfolio of satisfied clients.

2. Range of Services

Ensure the provider offers a comprehensive range of services, including cutting, bending, welding, punching, and finishing. This will save you the hassle of working with multiple vendors.

3. Material Expertise

Different projects require different materials, such as aluminum, stainless steel, or galvanized steel. Choose a manufacturer like Sinoway that has expertise in working with various materials.

4. Turnaround Time

Time is often of the essence in manufacturing. Verify the provider’s production capacity and lead times to ensure they can meet your deadlines without compromising quality.

5. Certifications and Compliance

Check if the company adheres to industry standards and certifications. Sinoway, for example, complies with ISO standards, ensuring high-quality and reliable products.

Steps to Partner with Sinoway

If you’ve decided to work with Sinoway for your sheet metal processing needs, here’s how to get started:

1. Initial Consultation

Reach out to Sinoway to discuss your project requirements. Their team will provide expert guidance on the best solutions for your needs.

2. Quotation and Proposal

After understanding your requirements, Sinoway will provide a detailed quotation and project proposal. This will include cost estimates, timelines, and technical specifications.

3. Prototyping and Testing

Before full-scale production, Sinoway can create prototypes to ensure the design and functionality meet your expectations. This step minimizes risks and ensures a smooth production process.

4. Production and Delivery

Once the prototype is approved, Sinoway will proceed with production. They maintain strict quality control measures to ensure the final product meets your specifications. The finished components will then be delivered to your location promptly.

Conclusion

Choosing the right sheet metal processing service provider is a critical decision that can significantly impact your business operations. By partnering with a reliable and experienced manufacturer like Sinoway, you can ensure high-quality, cost-effective, and timely solutions for your sheet metal needs.

Remember to evaluate potential service providers based on their experience, range of services, material expertise, turnaround time, and compliance with industry standards. With its advanced technology, skilled workforce, and commitment to quality, Sinoway stands out as a trusted partner for businesses across various industries.

Take the time to assess your specific requirements and reach out to Sinoway for a consultation. By doing so, you’ll be well on your way to achieving manufacturing excellence and driving your business forward.