The Steel Casting Process: From Design to Finished Product

Steel casting is a complex, precise, and highly engineered process that transforms raw materials into robust, functional components for various industries. At Sinoway, a leading sheet metal manufacturer, we specialize in delivering high-quality steel castings tailored to the specific needs of our clients. In this comprehensive article, we’ll walk you through the steel casting process, from initial design to the finished product, highlighting the latest advancements and the integral role of sheet metal fabrication.

Understanding Steel Casting

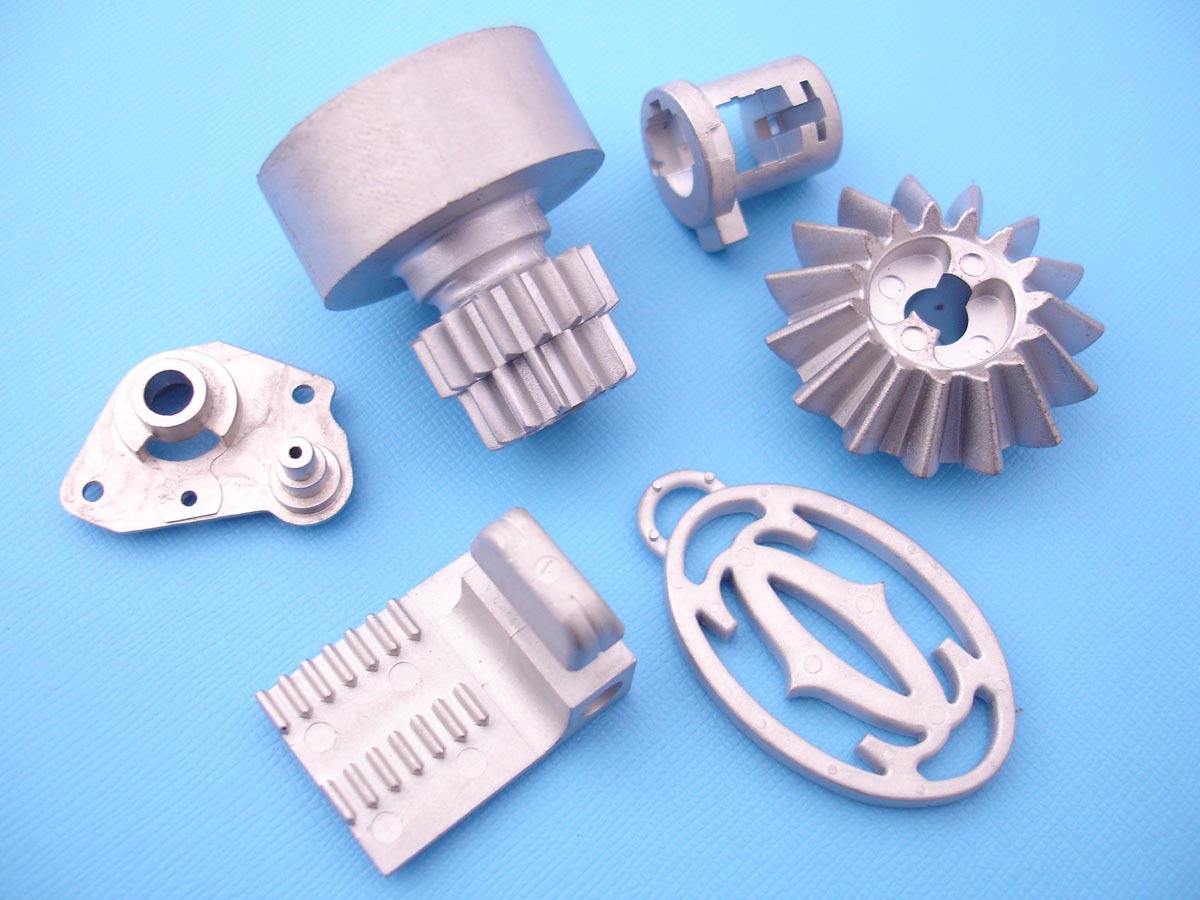

Steel casting involves pouring molten steel into a mold to create parts with intricate shapes and superior mechanical properties. This process is widely used across industries such as automotive, construction, energy, and heavy machinery. Sinoway’s expertise as a sheet metal manufacturer ensures that each casting meets stringent quality and performance standards.

Step 1: Design and Engineering

The journey of steel casting begins with a detailed design phase. At Sinoway, our engineering team collaborates closely with clients to understand their requirements and application needs. Using advanced CAD (Computer-Aided Design) software, we create precise 3D models of the desired component. This digital blueprint allows for simulation and analysis, ensuring the final product will perform optimally under operational conditions.

During this stage, manufacturability is a key consideration. Our engineers assess factors such as material selection, wall thickness, and tolerances, optimizing the design for both casting and subsequent sheet metal fabrication processes.

cast steel valves

shell mold casting products category

cast iron burner

self locking wire rope grip

stainless steel pipe elbows

Step 2: Pattern and Mold Making

Once the design is finalized, the next step involves creating a physical pattern—an exact replica of the final part. Patterns can be made from wood, plastic, or metal, depending on the complexity and production volume. At Sinoway, we utilize state-of-the-art CNC machines to produce highly accurate patterns.

The pattern is then used to create the mold. In steel casting, sand molds are most common due to their versatility and cost-effectiveness. The mold consists of two halves, which are assembled to form a cavity matching the shape of the desired component.

Step 3: Melting and Pouring

Steel, known for its strength and durability, is melted in high-temperature furnaces. At Sinoway, we employ both electric arc and induction furnaces to achieve precise temperature control and alloy composition. The molten steel is carefully poured into the prepared mold, filling every contour and detail.

This stage is critical, as the quality of the pour directly affects the structural integrity of the final product. Our experienced operators monitor the process closely, ensuring consistency and minimizing defects.

Step 4: Cooling and Solidification

After pouring, the steel cools and solidifies within the mold. The cooling rate is controlled to prevent internal stresses and ensure uniform grain structure. Depending on the size and complexity of the casting, this process can take several hours.

Once solidified, the mold is broken away to reveal the raw casting. At Sinoway, we prioritize efficient mold removal methods to protect the integrity of the component.

Step 5: Cleaning and Finishing

The freshly cast part undergoes cleaning to remove residual sand, scale, and surface imperfections. Techniques such as shot blasting, grinding, and machining are employed to achieve the desired finish and dimensional accuracy.

As a sheet metal manufacturer, Sinoway integrates sheet metal fabrication techniques at this stage. Processes like welding, bending, and surface treatment enhance the functionality and appearance of the steel casting, preparing it for its intended application.

Step 6: Quality Inspection

Quality assurance is central to the steel casting process at Sinoway. Each casting undergoes rigorous inspection using both non-destructive and destructive testing methods. Common tests include ultrasonic testing, X-ray inspection, and tensile strength analysis.

Our commitment to precision ensures that every product meets or exceeds industry standards, providing clients with reliable, high-performance components.

Step 7: Assembly and Delivery

For many projects, the steel casting is just one part of a larger assembly. Sinoway’s integrated manufacturing capabilities allow us to assemble complex products, incorporating sheet metal parts and other components as required.

Finished products are thoroughly packaged and delivered to clients worldwide, ready for installation or further processing.

Latest Trends in Steel Casting and Sheet Metal Manufacturing

The steel casting industry is continually evolving, with new technologies driving improvements in efficiency, quality, and sustainability. At Sinoway, we embrace innovations such as additive manufacturing (3D printing) for rapid prototyping, advanced simulation software for process optimization, and eco-friendly practices to reduce environmental impact.

As a sheet metal manufacturer, Sinoway also leverages automation and robotics to enhance productivity and ensure consistent quality across all stages of production.

Table: Key Steps in the Steel Casting Process

| Step | Description |

|---|---|

| Design & Engineering | Creating digital models and simulations |

| Pattern & Mold Making | Producing patterns and forming molds |

| Melting & Pouring | Heating steel and pouring into molds |

| Cooling & Solidification | Controlled cooling to form solid parts |

| Cleaning & Finishing | Surface treatment and dimensional adjustments |

| Quality Inspection | Testing for defects and verifying specifications |

| Assembly & Delivery | Final assembly and shipment to clients |

Integrating CNC Machining and Sheet Metal Fabrication

One of the major advancements in modern steel casting is the integration of CNC machining. CNC machining allows for highly accurate post-casting modifications, ensuring that each component meets exact specifications. At Sinoway, our CNC machining capabilities complement our sheet metal fabrication services, providing clients with turnkey solutions for even the most complex projects.

This seamless integration reduces lead times, minimizes errors, and offers greater flexibility in product design and customization.

Applications of Steel Casting

Steel castings produced by Sinoway serve a wide array of industries. In automotive manufacturing, they are used for engine blocks, transmission housings, and suspension components. In the construction sector, steel castings form the backbone of structural frameworks and heavy equipment.

Our expertise as a sheet metal manufacturer extends to producing enclosures, brackets, and custom parts that enhance the performance and longevity of steel castings in demanding environments.

Environmental Responsibility in Steel Casting

Sustainability is a growing priority in the steel casting industry. Sinoway is committed to reducing waste, conserving energy, and recycling materials wherever possible. By adopting green manufacturing practices, we help our clients achieve their environmental goals while maintaining the highest standards of quality.

Our investment in modern equipment and continuous training ensures that we remain at the forefront of eco-friendly steel casting and sheet metal manufacturing.

Conclusion: Why Choose Sinoway?

The steel casting process is a blend of art, science, and engineering. From initial design to the finished product, every step requires precision, expertise, and a commitment to quality. As a trusted sheet metal manufacturer, Sinoway delivers comprehensive solutions that meet the diverse needs of our clients.

Whether you require a single prototype or large-scale production, our advanced capabilities, skilled workforce, and customer-focused approach make Sinoway your ideal partner for steel casting and sheet metal fabrication.

Contact us today to learn how we can help bring your next project to life with exceptional steel castings and sheet metal solutions.