In today’s fast-paced manufacturing landscape, product design and development must keep up with evolving customer demands, technological innovations, and market competition. One of the most effective ways to enhance product design is through custom sheet metal processing. As a leading sheet metal manufacturer, Sinoway is committed to helping businesses unlock new levels of quality, efficiency, and design flexibility with advanced sheet metal solutions.

Why Custom Sheet Metal Processing Matters in Product Design

Product design is not just about aesthetics — it’s about functionality, manufacturability, and cost-effectiveness. Custom sheet metal processing empowers designers and engineers to create components that precisely fit their requirements. This approach enables faster prototyping, improved structural integrity, and seamless integration into the final product.

The Sinoway Advantage: Expertise in Sheet Metal Manufacturing

Sinoway stands out as a trusted sheet metal manufacturer with years of experience serving diverse industries, from electronics to automotive and medical equipment. Our team leverages state-of-the-art equipment and deep technical knowledge to deliver custom sheet metal parts that meet the highest standards. Whether you need intricate enclosures, robust brackets, or complex assemblies, Sinoway ensures precision and consistency at every stage.

Key Benefits of Custom Sheet Metal Processing

- Design Flexibility: Custom processing allows for unique shapes, sizes, and finishes that standard components can’t offer.

- Rapid Prototyping: Quickly iterate and test new ideas, reducing time-to-market for innovative products.

- Cost Efficiency: Minimize material waste and assembly time with tailored solutions.

- Enhanced Performance: Optimize strength, weight, and durability according to specific application needs.

- Scalability: Easily transition from prototype to mass production without compromising quality.

Integrating Custom Sheet Metal Processing into Your Product Design Workflow

The integration of custom sheet metal processing begins at the earliest stages of product design. Sinoway’s engineering team collaborates closely with clients to understand functional requirements, material preferences, and performance goals. This partnership-driven approach ensures every detail is considered, from material selection to finishing processes.

Step-by-Step Process at Sinoway

| Step | Description |

|---|---|

| 1. Consultation & Design Review | Work with Sinoway’s engineers to review concepts, CAD drawings, and specifications. |

| 2. Material Selection | Choose from a wide range of metals and alloys based on strength, weight, and corrosion resistance. |

| 3. Prototyping | Create rapid prototypes for testing and validation. |

| 4. Production | Utilize advanced fabrication techniques such as laser cutting, bending, punching, and welding. |

| 5. Quality Control | Comprehensive inspections to ensure dimensional accuracy and surface finish. |

| 6. Finishing & Assembly | Apply coatings, painting, or assembly as required. |

Latest Trends in Sheet Metal Processing

The sheet metal industry is continuously evolving with new technologies and methodologies. At Sinoway, we embrace the latest advancements such as precision fiber laser cutting, automated bending, and digital manufacturing workflows. These innovations not only improve speed and accuracy but also open up new possibilities for complex geometries and lightweight structures.

Embracing Sustainability in Sheet Metal Manufacturing

Sustainability is increasingly important in product design. Sinoway is dedicated to minimizing environmental impact by optimizing material usage, recycling scrap metal, and reducing energy consumption. Our commitment to eco-friendly practices ensures that your products align with modern sustainability standards.

Case Study: Custom Sheet Metal Processing in Electronics Enclosures

A global electronics company approached Sinoway for custom sheet metal enclosures that required precise dimensions, effective heat dissipation, and high aesthetic appeal. By leveraging our advanced processing capabilities, we delivered a solution that met all requirements and enhanced the end-user experience. The project demonstrated how custom sheet metal processing can transform product functionality and marketability.

How Sinoway Supports Your Product Innovation

From concept to completion, Sinoway partners with clients to overcome design challenges and realize their vision. Our responsive customer service, technical expertise, and robust production capabilities make us the preferred sheet metal manufacturer for businesses seeking a competitive edge.

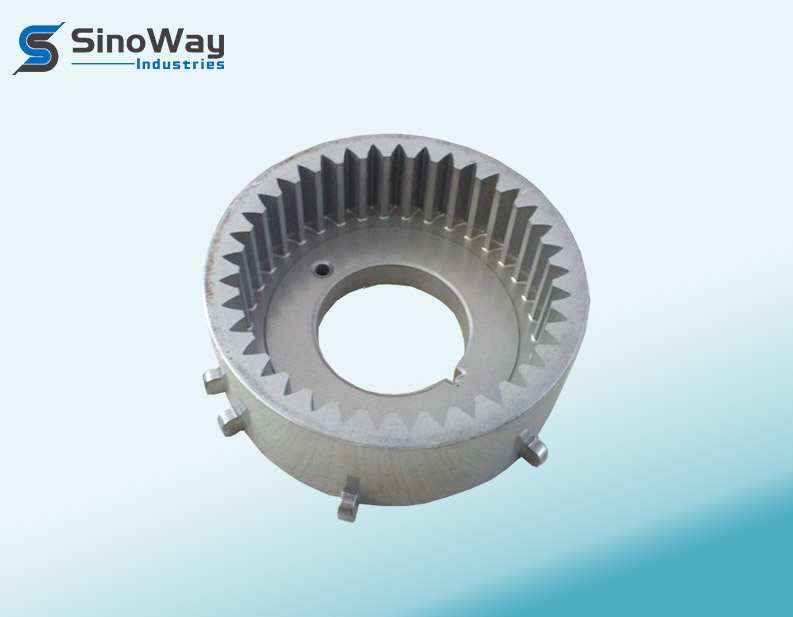

Integrating CNC Machining and Metal Fabrication

Two related keywords in the manufacturing industry are CNC machining and metal fabrication. While custom sheet metal processing is central to Sinoway’s services, we also integrate CNC machining for high-precision components and offer comprehensive metal fabrication solutions. This holistic approach ensures clients receive fully finished parts that meet exacting standards for fit, form, and function.

Why Combine CNC Machining and Metal Fabrication?

- Precision: CNC machining delivers tight tolerances for critical features.

- Complexity: Metal fabrication enables the creation of assemblies and structures that go beyond simple sheet metal parts.

By combining these technologies, Sinoway provides a one-stop solution for product designers seeking versatility and reliability.

Conclusion: Drive Product Excellence with Sinoway

Custom sheet metal processing is a powerful tool for improving product design, enhancing performance, and accelerating innovation. As a forward-thinking sheet metal manufacturer, Sinoway offers the expertise, technology, and customer focus needed to bring your ideas to life. Whether you’re developing a new product or optimizing an existing one, partner with Sinoway to achieve superior results.

Ready to take your product design to the next level? Contact Sinoway today to explore how our custom sheet metal processing, CNC machining, and metal fabrication services can help you succeed in a competitive marketplace.