Sinoway Industry company is a company specializing in various types of metal stamping parts and sheet metal processing. We are located in Qingdao, Shandong, close to the port. We have been focusing on the processing and manufacturing of metal parts for many years. The products we have produced include laser cutting parts,die casting parts,sand casting parts,mechanical machining parts,metal stamping parts,press bending parts,lost foam casting parts,shell mold casting parts,deep drawing parts, etc. We provide services such as welding,CNC machining,surface finishing,powder metallurgy,sheet metal manufacturing,drop forging, etc.

For stamping business, we have strong mold design and production capabilities, can design and manufacture new molds and respond to changes quickly, and can provide solutions for various types of high-difficulty metal stamping parts. Our customized production lines include sheet metal fabricating lines,metal casting lines,metal powder metallurgy lines,metal parts machining lines,robot welding lines, etc. We always put quality control in the first place and keep improving. We have been committed to achieving high quality products, competitive prices and on-time delivery.

The following table information is reference data about aluminum die casting companies:

| Type | metal parts |

| Brand Name | Sinoway |

| Place of Origin | Qingdao, Shandong, China |

| Sample | Availble |

| Application | furniture fabrication,heavy equipment…etc |

| OEM and ODM | Yes |

| Size | Custom |

| Logo | receive customization |

| Packing | based on the requirements of the clients |

| Certificate | ISO 9001…. |

| Payment | T/T,Western Union,L/C payment…etc |

| Delivery(Days) | 25-30 |

Please note: The above table data is for reference only. For specific information, please contact us.

As a aluminum die casting companies, we provides custom manufacturing solutions to clients throughout the world. We can manufacture built-to-order parts, custom products and offer a wide variety of options to meet your demands. We can support high volumes, short-lead times, and additive manufacturing services.

How To Work With Us?

Phase 1

Send us the design or manufacturing drawings for evaluation. Both 2D and 3D files are acceptable.

Phase 2

Discuss the metal parts’ manufacturability and interchangeability to fix the final design.

Phase 3

Make the quote, confirm the order, and start tooling, modeling, and mass production.

Phase 4

Inspect the cargoes, package up, and arrange the delivery to you.

Booth at the exhibition

This is our workshop

This is our factory

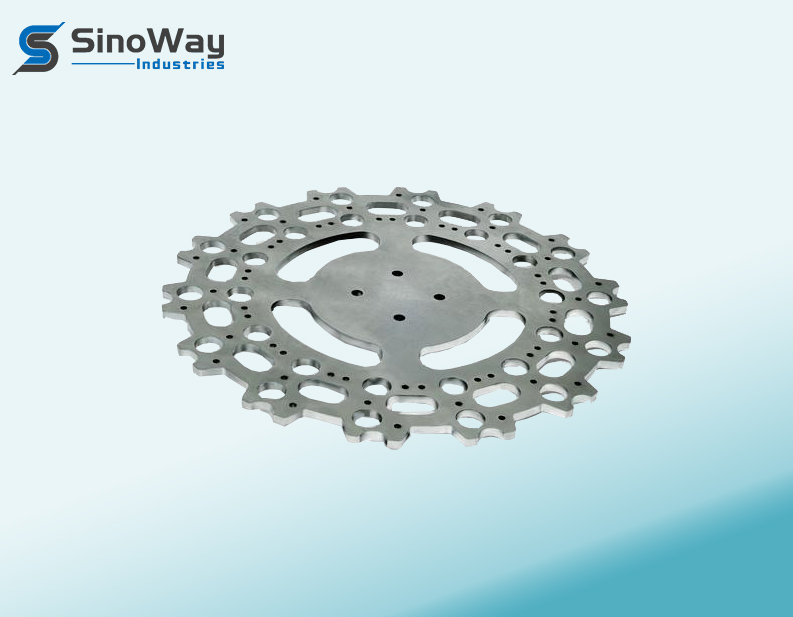

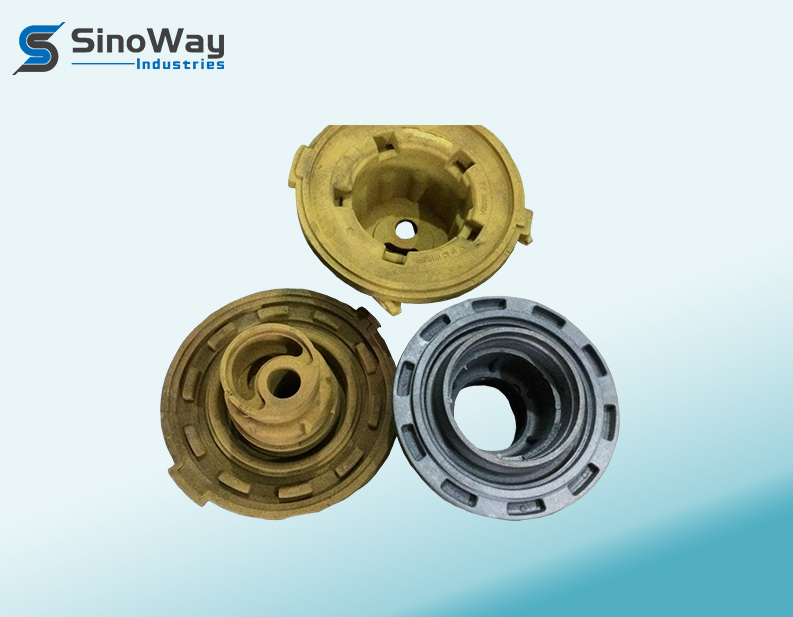

Some of our products