Sand casting, investment casting (lost wax casting), and pressure casting are three of the most popular and widely used casting methods. Most metal casting parts commonly used in various industries are made by one of these three processes.

This article will introduce these three most common casting processes one by one.

What is a sand casting process?

Let’s take a look at the introduction to Sand casting in Wikipedia (interested readers may click this link to Wikipedia’s detailed description page).

“Sand casting, also known as Sand molded casting, is a metal casting process characterized by using Sand as the mold material. ”

Yes, when we use a sand mold for casting, we can call it Sand Casting for the process.

And it says over 60% of all metal castings are produced via the sand casting process.

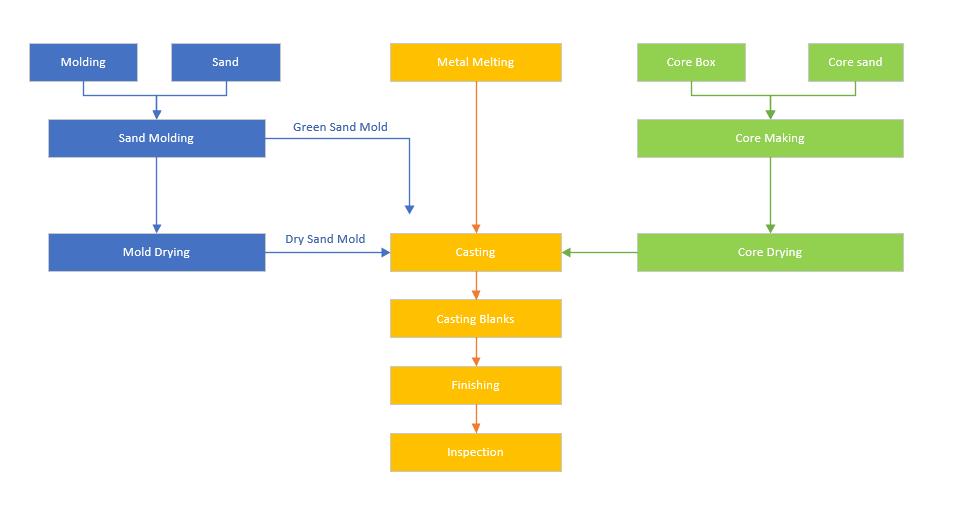

Processing flows of sand casting

The general flow of the sand casting process includes sand making, core making, casting, and post-processing. The diagram below shows the process flows.

Parameters to be considered in the sand casting process

- Machining allowance. For those surfaces that need to be machined on the casting, we should reserve a machining allowance in advance while doing the casting design. The machining allowance depends on the casting alloy, molding method, the size of the casting and the location of the machined surface in the mold, and many other factors.

- Draft angle. To make the casting easy to be taken out from the mold, the slope on the vertical wall of the mold perpendicular to the parting surface is called draft angle.

- Casting fillet. In order to prevent castings from stress and cracks and avoid damage to the sharp corners and formation of sand holes, the castings should be designed with fillets at the joints and corners.

- Core Head. The core head should be designed for both the mold and the core to ensure the core’s positioning, fixing, and venting.

- Shrinkage allowance. Due to the shrinkage after pouring, compensation should be applied to these dimensions while casting.

Advantages of Sand Casting

- Clay is abundant and inexpensive. Most of the green sand made of clay can be recycled and reused.

- The production period of the casting mold is short, so the molding efficiency of sand casting is relatively high.

- The service life of the molding sand is rather long.

- The applicability of sand casting is vast. Whether the workpiece is small or large, simple or complicated, it is possible to use the sand casting process for individual production or mass production.

Disadvantages of Sand Casting

- Each sand mold can only be poured once because it will be damaged after casting. We must re-mold it again, so the production efficiency of sand casting is relatively low.

- The rigidity of the casting is not high, and the dimensional accuracy is poor.

- The casting is very easily defective, such as sand washing, sand trapping, and blowhole.

What is investment casting?

In the investment casting process, we usually use fusible material to make the pattern and cover it with several layers of refractory material to make the shell. Then we need to melt the pattern and discharge it to obtain a hollow body without parting lines. And then, after high-temperature roasting, we can fill and pour for the castings.

As the pattern is widely used in wax material, investment casting is often called “lost wax casting.”

Materials suitable for investment casting

The types of alloys available for investment casting include carbon steel, alloy steel, heat-resistant alloys, stainless steel, precision alloys, permanent magnet alloys, bearing alloys, copper alloys, aluminum alloys, titanium alloys, ductile iron, etc.

Processing flows of investment casting

The workflows of the investment casting process include wax pattern making, shell making, de-waxing, shell baking, pouring, and post-treatment. We can refer to the diagram shown below.

Advantages of Investment casting

- High dimensional accuracy. Generally up to CT4-6 (CT10~13 for sand casting and CT5~7 for die casting).

- It can improve the utilization rate of metal materials. Investment casting can significantly reduce the machining amount of the product and save machining time and materials consumption.

- It can maximize the similarity between the casting blank and the part, which brings great convenience to the structural design of the part. Investment casting can cast very complicated shapes, castings with thicknesses of 0.5 mm and weighing down to 1 gram, and cast combined integral parts.

- The investment casting process is not limited by the alloy material. It can cast carbon steel, alloy steel, ductile iron, copper alloy, aluminum alloy parts, high-temperature alloys, magnesium alloys, titanium alloys, precious metals, and other alloyed materials.

The alloy materials that are difficult to forge, weld, and machine are particularly suitable for the precision casting method. - High production flexibility and adaptability. Investment casting is suitable for high-volume production, small-volume production, or even single-piece production.

Disadvantages of Investment casting

- The size of the casting cannot be too large.

- The process is complicated, so the production period is relatively long.

- The cooling rate of the castings is not fast.

Investment casting is the most complex among all blank forming methods, and the casting costs are significantly high. However, if the product is properly designed, the high casting costs will be compensated by the reduction of machining, the saving of assembly time, and the saving of metal materials.

Principle of Die Casting

The principle of the die casting process is to utilize pressure to push the molten metal into the cavities of the precision mold at high speed, and the castings will be cooled and solidified under pressure.

Materials suitable for Die Casting

The main die casting alloys are zinc, aluminum, magnesium, copper, lead, and tin; although uncommon, ferrous die casting is also possible. For example, common grades of die-cast aluminum alloys include AA 380, AA 384, AA 386, AA 390, AZ91D magnesium, etc.

Types of Die Casting

There are two basic die casting methods: hot-chamber die casting and cold-chamber die casting.

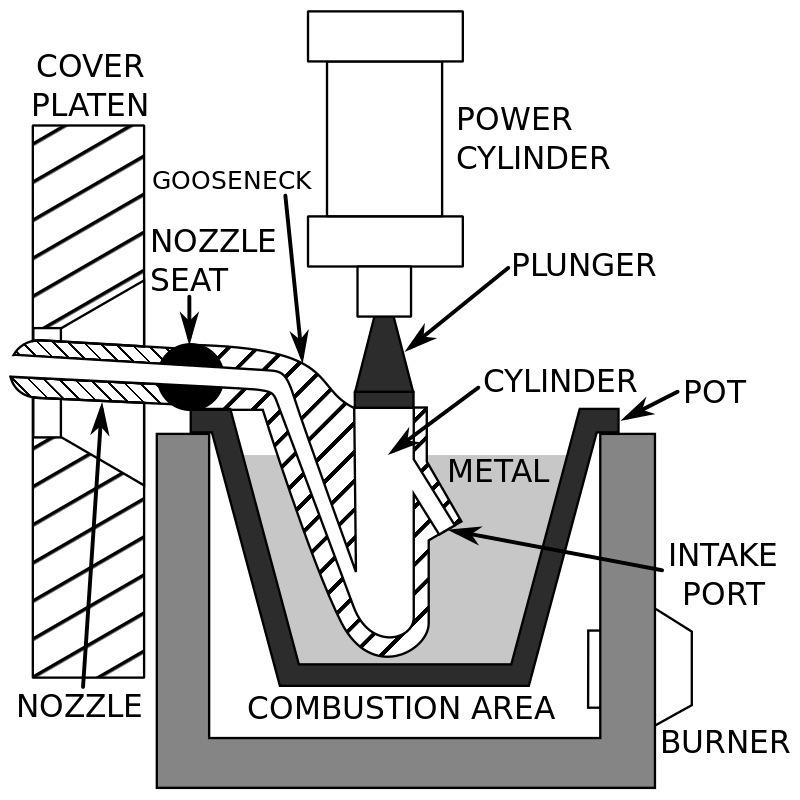

Hot-chamber die casting

Hot-chamber die casting relies upon a pool of molten metal to feed the die in the same machine.

The advantages of this system include fast cycle times (approximately 15 cycles a minute) and the convenience of melting the metal in the casting machine.

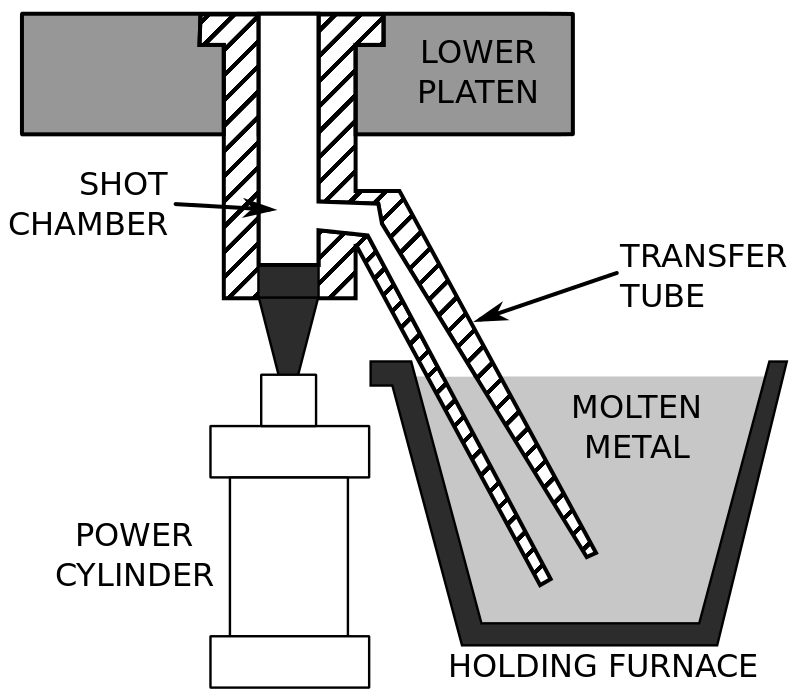

Cold-chamber die casting

Cold-chamber die casting is used when the casting alloy cannot be used in hot-chamber machines; these include aluminum-zinc alloys with a large composition of aluminum, magnesium, and copper.

Compared to Hot-chamber die casting, the most significant disadvantage of this system is the slower cycle time due to the need to transfer the molten metal from the furnace to the cold-chamber machine.

Processing flows of die casting

The following are the four steps in traditional die casting, also known as high-pressure die casting. These are also the basis for any of the die casting variations:

- Die preparation. The dies are prepared by spraying the mold cavity with lubricant.

- Filling. Molten metal is injected into the dies under high pressure after the dies close. Once the mold cavity is filled, the pressure is maintained until the casting solidifies.

- Ejection. The dies are then opened, and the shot (shots are different from castings because there can be multiple cavities in a die, yielding multiple castings per shot) is ejected by the ejector pins.

- Shakeout. Finally, the shakeout involves separating the scrap from the shot, which includes the gate, runners, sprues, and flash.

Advantages of die casting

- Excellent dimensional accuracy.

- Smooth cast surfaces.

- Thinner walls can be cast as compared to sand and permanent mold casting.

- Reduces or eliminates secondary machining operations.

- Rapid production rates.

Disadvantages of die casting

- The main disadvantage to die casting is the high capital cost. Both the casting equipment required and the dies and related components are very costly compared to most other casting processes. Therefore, a large production volume is needed to make die casting economical.

- The process is limited to high-fluidity metals.

- Die casting involves many parts, so questions of repeatability are crucial.

- Casting weights have previously been limited to between 30 grams (1 oz) and 10 kg (20 lb), but from 2018 shots of 80 kilograms (180 lb) have become possible.

- In the standard die casting process, the final casting will have a small amount of porosity.

Conclusion

Each casting method has both advantages and disadvantages.

In practical applications, we should select the most suitable casting process for our products based on the material, shape, performance, manufacturing cost, and the respective functions needed to achieve.