In today’s fast-paced manufacturing environment, high-precision components are critical to the performance and reliability of products across industries such as automotive, aerospace, electronics, and medical devices. Complex metal stamping has emerged as a key process in producing intricate parts that demand tight tolerances, exceptional material properties, and reliable performance.

At Sinoway, we specialize in complex metal stamping, leveraging advanced technology and expertise to deliver parts that meet the highest standards of quality and precision. In this article, we’ll explore the role of complex metal stamping in high-precision applications, the benefits it offers, and the key considerations when selecting a stamping supplier.

What is Complex Metal Stamping?

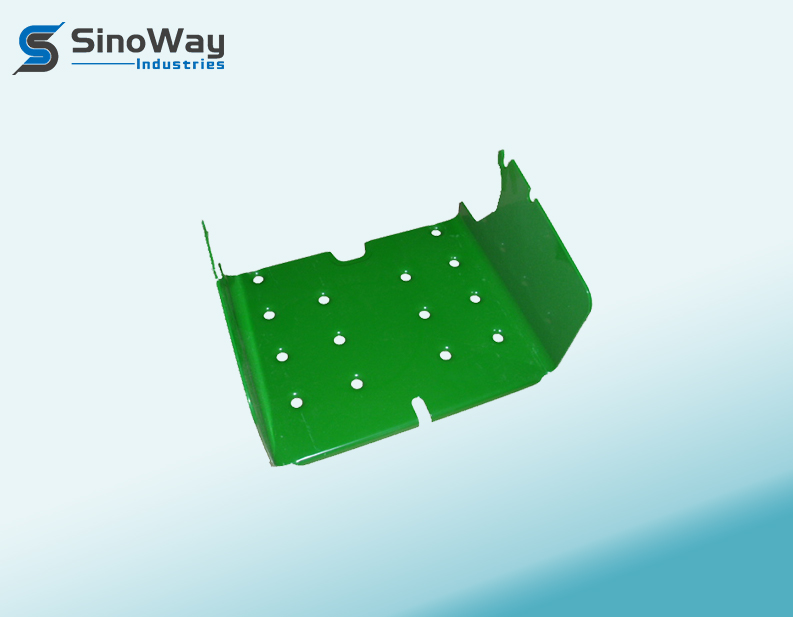

Complex metal stamping is a manufacturing process that involves shaping and cutting metal sheets into precise, intricate components using a stamping press and dies. This process is particularly useful for producing parts with complex geometries that require high accuracy, such as connectors, housings, brackets, and enclosures. Metal stamping is widely used in various industries, including automotive, electronics, medical, and consumer products, where precision and consistency are paramount.

Key Features of Complex Metal Stamping:

- Intricate Shapes: Complex metal stamping can produce parts with highly detailed shapes, including multi-dimensional features.

- High Precision: The process achieves tight tolerances, often as low as ±0.001 inches, making it ideal for high-precision applications.

- Scalability: Stamping can be used for both small-batch production and large-volume runs, making it versatile for different project sizes.

At Sinoway, we specialize in producing high-precision stamped components for industries that demand reliability and accuracy, using advanced equipment and years of expertise.

The Benefits of Complex Metal Stamping for High-Precision Applications

1. Precision and Accuracy

The most significant advantage of complex metal stamping is its ability to produce highly accurate parts with tight tolerances. When designing components that require exact specifications—whether for assembly or performance—precision is critical. Metal stamping ensures that every part is produced with minimal variation, making it a reliable choice for industries such as automotive, aerospace, and electronics.

How Precision is Achieved:

- CNC Press Machines: Modern CNC-controlled stamping presses ensure that every part is manufactured consistently and accurately.

- High-Quality Dies: The use of high-precision dies allows for detailed cuts and forms that replicate designs with extreme accuracy.

- Inspection and Testing: In-house quality control and testing, such as dimensional inspections and functional testing, further guarantee that parts meet the required specifications.

At Sinoway, our advanced CNC stamping machines and strict quality control processes ensure that every part is made with exceptional precision, meeting the specific needs of high-performance applications.

2. Material Efficiency

One of the challenges in high-precision manufacturing is optimizing material use. With complex metal stamping, it’s possible to reduce material waste while still achieving high-quality components. This is particularly important in industries that require the use of expensive or high-performance materials like stainless steel, aluminum, or titanium.

Key Material Efficiency Benefits:

- Minimal Waste: Complex stamping techniques use advanced die designs that minimize scrap material, reducing costs and improving material utilization.

- Custom Material Options: Metal stamping can work with a wide variety of materials, allowing businesses to choose the right one for their specific application, whether it’s a durable alloy or lightweight material.

Sinoway’s stamping processes are designed to maximize material efficiency, ensuring that you get the most out of every sheet of metal while keeping production costs down.

3. Speed and Scalability

Metal stamping is a fast, efficient process that can produce large quantities of high-precision parts in a relatively short time. For high-volume production, this means faster turnaround times and reduced lead times. For low-volume, custom, or prototyping work, it still offers speed compared to traditional machining processes.

Speed and Scalability in Stamping:

- High-Speed Production: Stamping presses can produce hundreds or even thousands of parts per hour, depending on the complexity and size of the components.

- Flexibility: Whether your project requires large-scale production or small batch runs, metal stamping can accommodate both needs efficiently.

- Cost-Effectiveness: With the combination of speed and precision, metal stamping offers a cost-effective solution for high-precision components, even for large production volumes.

At Sinoway, we are equipped with high-speed stamping presses that can handle both high-volume and custom orders, providing you with fast and reliable delivery for any project size.

4. Durability and Strength

Complex metal stamping is particularly effective for producing components that require high strength and durability. The stamping process can work with a range of materials that offer superior mechanical properties, such as stainless steel or high-strength alloys. These materials provide the durability necessary for parts that will be subjected to wear, pressure, or extreme conditions.

Why Durability Matters:

- Load-Bearing Parts: Many industries, such as automotive or aerospace, require stamped components to withstand heavy loads and high stress.

- Corrosion Resistance: Materials like stainless steel and coated alloys are resistant to corrosion, making them ideal for parts exposed to harsh environments.

- Wear Resistance: Stamped components can be made to withstand abrasion and impact, making them suitable for applications like gears, housings, and brackets.

Sinoway utilizes a wide range of materials with excellent durability and strength to produce parts that meet the most demanding performance requirements.

Key Considerations When Selecting a Complex Metal Stamping Supplier

1. Experience and Expertise

Choosing the right metal stamping supplier is crucial for ensuring that your high-precision parts are manufactured to meet your exact specifications. An experienced supplier will have the necessary knowledge to handle complex designs, select the right materials, and produce parts with the required accuracy.

Why Experience Matters:

- Technical Knowledge: Suppliers with experience in stamping can understand your project’s unique requirements and recommend the best approach.

- Problem-Solving: An experienced supplier can address potential challenges in design, materials, or production techniques.

- Consistency: Long-term experience often leads to more consistent results, especially when dealing with complex stamping jobs.

At Sinoway, our extensive experience in complex metal stamping ensures that we can meet your high-precision requirements with consistent results.

2. Capabilities and Technology

The technology and equipment used by a stamping supplier are key factors in determining the quality and precision of the finished parts. A good supplier will use advanced stamping machines, high-quality dies, and cutting-edge tools to ensure that every part is produced to exact specifications.

What to Look for in a Stamping Supplier:

- CNC Press Machines: Modern CNC presses provide superior accuracy and speed, essential for high-precision applications.

- Advanced Die Design: Sophisticated dies ensure that complex geometries and tight tolerances can be achieved consistently.

- Automated Processes: Automation improves efficiency and reduces human error, ensuring high-volume consistency.

Sinoway uses the latest CNC-controlled stamping presses and advanced die design techniques to ensure the highest level of precision for your parts.

3. Quality Control and Certification

Quality control is a crucial aspect of the complex metal stamping process. The supplier should have robust quality control measures in place, including in-process inspections, final part testing, and certifications that demonstrate their commitment to high standards.

Key Quality Control Practices:

- ISO Certifications: Look for suppliers with ISO 9001 certification, which demonstrates their adherence to international quality management standards.

- Inspection and Testing: Suppliers should conduct dimensional checks, visual inspections, and functional testing to ensure part quality.

- Traceability: A reliable supplier will maintain full traceability for every part produced, enabling quick identification and resolution of any issues.

At Sinoway, we employ strict quality control protocols and hold ISO 9001 certification, ensuring that each stamped component meets the highest quality standards.

4. Customization and Design Flexibility

Complex metal stamping often involves working with custom designs, especially when the parts are intended for high-precision applications. It’s important to choose a supplier who can handle custom tooling and offer design flexibility to meet your unique needs.

Why Customization is Crucial:

- Tailored Components: Custom designs ensure that your parts are optimized for your specific application, whether it’s for fit, function, or performance.

- Prototyping: Many suppliers offer prototyping services, allowing you to test the design before committing to full-scale production.

- Design Assistance: A skilled supplier can help refine your designs to ensure they’re manufacturable and cost-effective.

Sinoway specializes in custom metal stamping, offering prototyping and full-scale production to bring your unique designs to life with precision and efficiency.

Conclusion: Why Sinoway is Your Trusted Partner for Complex Metal Stamping

Complex metal stamping is an essential process for producing high-precision components that meet the demands of industries such as automotive, aerospace, and electronics. By choosing the right supplier, you ensure that your parts are produced with the highest accuracy, efficiency, and durability.

At Sinoway, we offer advanced metal stamping services with a focus on precision, material efficiency, and customization. With over a decade of experience, state-of-the-art technology, and a commitment to quality, we are your trusted partner for high-precision metal stamping applications.

If you’re looking for a reliable supplier for complex metal stamping, contact Sinoway today to learn how we can help you meet your project goals with precision and efficiency.