In the modern manufacturing landscape, the demand for lightweight yet robust components is ever-increasing. Industries ranging from automotive to aerospace are constantly on the lookout for materials and processes that can deliver these attributes. One such process that has gained significant traction is thin metal punching. Sinoway, a leading sheet metal manufacturer, is at the forefront of leveraging this technique to produce components that meet stringent industry standards.

Introduction to Thin Metal Punching

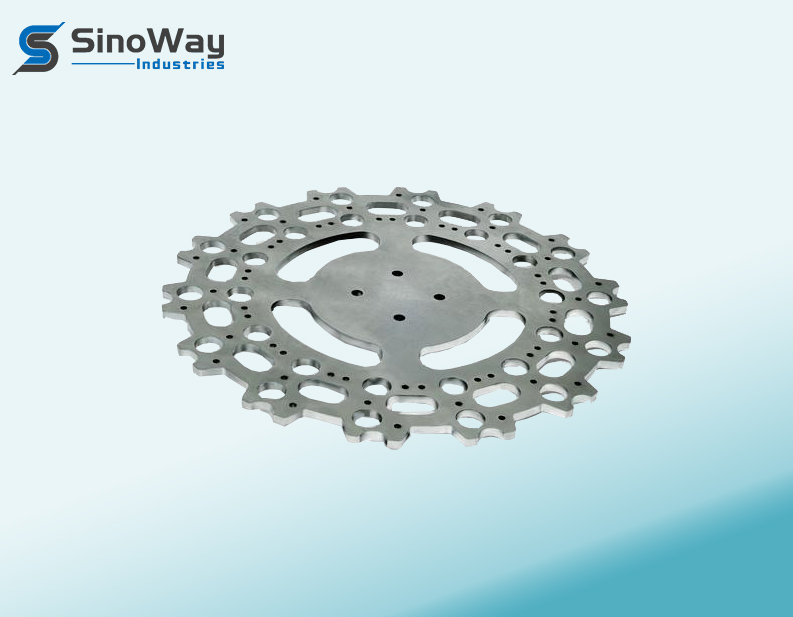

Thin metal punching is a manufacturing process that involves the use of specialized machinery to cut and shape metal sheets into desired forms. This technique is particularly advantageous for producing components that require precision and strength without the added weight of thicker materials. At Sinoway, we employ state-of-the-art technology to ensure that our punched metal components meet the highest quality standards.

Why Choose Thin Metal Punching?

There are several reasons why thin metal punching is a preferred choice for manufacturers:

- Lightweight Design: Components made through thin metal punching are inherently lighter, which is crucial for industries like aerospace and automotive where every gram counts.

- Strength and Durability: Despite their reduced weight, these components do not compromise on strength, making them suitable for high-stress applications.

- Cost Efficiency: Using less material not only reduces weight but also cuts down on costs, offering a more economical solution for manufacturers.

- Precision and Accuracy: The punching process allows for high precision, ensuring that components fit perfectly into their intended applications.

Applications of Thin Metal Punching

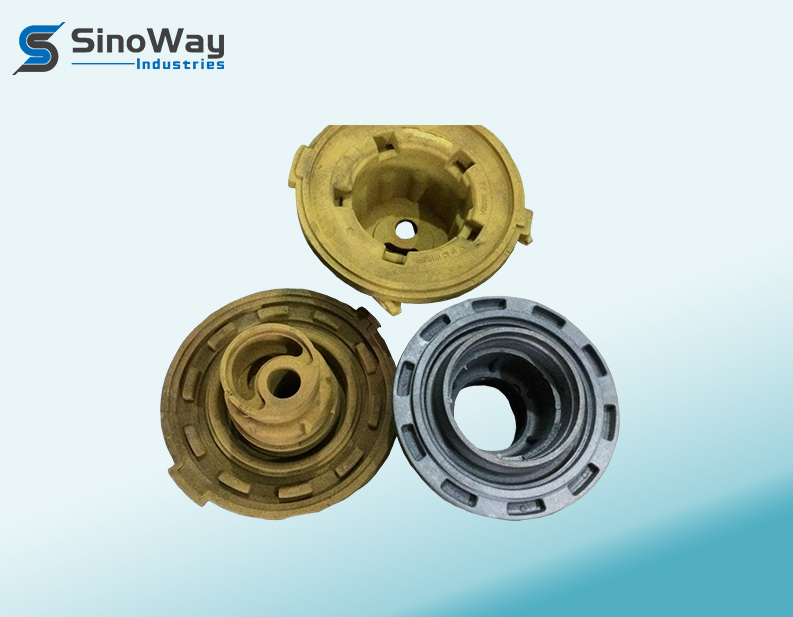

Thin metal punching is versatile and finds applications across various sectors. At Sinoway, we cater to a diverse range of industries, each with its unique requirements:

- Automotive Industry: Lightweight components are crucial for improving fuel efficiency and performance in vehicles.

- Aerospace Sector: Every gram saved in aircraft components contributes to better fuel efficiency and payload capacity.

- Electronics: Thin metal components are used in devices where space and weight are at a premium.

- Construction: Durable yet lightweight materials are ideal for modern construction needs.

Sinoway’s Expertise in Thin Metal Punching

As a leader in sheet metal manufacturing, Sinoway has honed its expertise in thin metal punching. Our commitment to quality and innovation sets us apart. Here’s how we ensure excellence in every project:

Advanced Machinery

We utilize cutting-edge punching machines that offer unparalleled precision and efficiency. Our equipment is regularly updated to incorporate the latest technological advancements, ensuring that we stay ahead of the competition.

Skilled Workforce

Our team comprises highly skilled professionals who are experts in metal fabrication. Continuous training and development programs ensure that our workforce remains adept at handling complex projects with ease.

Quality Assurance

Quality is at the heart of everything we do at Sinoway. We have stringent quality control measures in place to ensure that every component we produce meets the highest standards. From raw material selection to final inspection, every step is meticulously monitored.

Customization and Flexibility

We understand that every client has unique requirements. That’s why we offer customized solutions tailored to specific needs. Our flexible approach allows us to accommodate a wide range of specifications and deliver products that exceed expectations.

The Environmental Impact of Thin Metal Punching

In addition to its economic and performance benefits, thin metal punching also offers environmental advantages:

- Reduced Material Waste: The precision of the punching process minimizes waste, making it a more sustainable manufacturing option.

- Energy Efficiency: Producing lighter components requires less energy, contributing to a reduction in overall carbon emissions.

- Recyclability: Metal components are highly recyclable, allowing for the conservation of resources and reduction of landfill waste.

Conclusion

Thin metal punching is revolutionizing the way components are manufactured. Its ability to produce lightweight, strong, and cost-effective components makes it an invaluable process across multiple industries. Sinoway’s dedication to quality and innovation ensures that we remain a trusted partner for all your sheet metal needs. By choosing thin metal punching, you’re not only investing in superior components but also contributing to a more sustainable future.

For more information on how Sinoway can assist with your metal fabrication needs, please contact us. Our team is ready to provide expert guidance and solutions tailored to your specific requirements.