Metal drop forging has long been a cornerstone in the manufacturing world, providing unmatched strength and reliability for countless components. As industries evolve, so too does the technology and methodology behind this essential process. At Sinoway, a leading sheet metal manufacturer, we are at the forefront of embracing and driving these changes. In this article, we’ll explore the future of metal drop forging, highlighting innovations, emerging trends, and the strategic role of Sinoway in shaping the next generation of forged metal products.

Understanding Metal Drop Forging

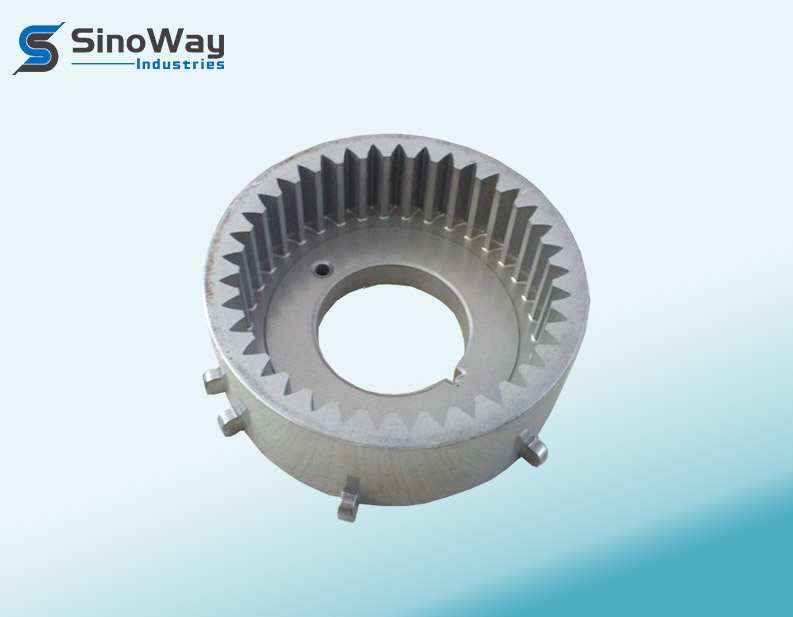

Metal drop forging involves shaping metal using localized compressive forces, typically delivered by a hammer or die. This process results in components with superior mechanical properties, making it ideal for critical applications across automotive, aerospace, construction, and more. As a sheet metal manufacturer, Sinoway leverages drop forging to deliver high-strength, precision components that meet the rigorous demands of modern industries.

Key Benefits of Metal Drop Forging

- Enhanced Mechanical Properties: Forged parts exhibit greater strength, ductility, and fatigue resistance compared to cast or machined counterparts.

- Cost Efficiency: High production rates and material utilization make drop forging an economical choice for large-scale manufacturing.

- Versatility: Suitable for a wide range of metals and alloys, from steel to aluminum.

Emerging Innovations in Metal Drop Forging

The future of metal drop forging is being shaped by several technological advancements. Let’s examine the most impactful innovations poised to redefine the industry.

1. Automation and Smart Manufacturing

Automation is revolutionizing metal drop forging by improving consistency, reducing human error, and enhancing throughput. Robotics and advanced sensors now handle everything from material handling to die alignment, ensuring precision at every step. At Sinoway, we integrate smart manufacturing solutions, utilizing real-time data analytics and machine learning to optimize forging parameters and predict maintenance needs.

casting oil seals

light truck front face

shell mold casting products category

cast steel valves

brackets for refrigerators

2. Advanced Simulation and Digital Twin Technology

Modern forging operations increasingly rely on simulation software and digital twins to model and refine processes before actual production. These tools allow engineers to predict material flow, temperature distribution, and potential defects, significantly reducing trial-and-error cycles. Sinoway’s engineering team uses these technologies to accelerate product development and ensure optimal quality from the outset.

3. Sustainable and Eco-Friendly Forging

Sustainability is a growing priority in manufacturing, and metal drop forging is no exception. Innovations such as energy-efficient induction heating, closed-loop cooling systems, and the use of recycled materials are reducing the environmental impact of forging operations. Sinoway is committed to green manufacturing, continuously investing in eco-friendly practices to minimize waste and energy consumption.

4. Customization and Rapid Prototyping

The demand for customized components and rapid prototyping is driving changes in forging technology. Flexible tooling, 3D printing for die production, and agile manufacturing systems enable faster turnaround times and greater design freedom. As a sheet metal manufacturer, Sinoway leverages these capabilities to deliver tailored solutions for clients across diverse industries.

Key Trends Shaping the Future of Metal Drop Forging

Beyond technological innovations, several broader trends are influencing the direction of the metal drop forging industry:

Integration of Sheet Metal Fabrication and Drop Forging

The convergence of sheet metal fabrication and drop forging processes is creating new opportunities for manufacturers. By combining the precision of sheet metal work with the strength of forged components, Sinoway delivers hybrid solutions that maximize both performance and cost-effectiveness. This integrated approach is particularly valuable in industries requiring complex assemblies with varying material thickness and properties.

Globalization and Supply Chain Optimization

As global supply chains become more interconnected, manufacturers must balance cost, quality, and lead times. Sinoway’s strategic location and robust logistics network enable us to serve international clients efficiently, ensuring reliable delivery of forged and sheet metal products worldwide.

Focus on Quality Assurance and Traceability

Advanced quality control systems, including non-destructive testing and digital traceability, are becoming standard in modern forging operations. Sinoway employs state-of-the-art inspection technologies to guarantee the integrity of every component, from raw material sourcing to final delivery.

Metal Drop Forging and Sheet Metal Manufacturer: Synergy for the Future

The synergy between metal drop forging and sheet metal manufacturing is unlocking new possibilities for product innovation. As a sheet metal manufacturer, Sinoway is uniquely positioned to harness this synergy, offering clients a comprehensive suite of services that spans design, prototyping, forging, and finishing.

Advantages of Partnering with Sinoway

- End-to-End Solutions: From concept to completion, Sinoway manages every stage of the manufacturing process.

- Expertise in Both Disciplines: Our team brings deep knowledge of both sheet metal fabrication and drop forging, ensuring optimal results for complex projects.

- Cutting-Edge Technology: Continuous investment in the latest tools and equipment keeps us ahead of industry trends.

- Commitment to Sustainability: Eco-friendly practices and materials help clients meet their environmental goals.

Challenges and Opportunities Ahead

While the future of metal drop forging is bright, the industry faces several challenges, including rising material costs, skilled labor shortages, and increasing regulatory requirements. However, these challenges also present opportunities for innovation and growth. By embracing digital transformation, investing in workforce development, and prioritizing sustainability, companies like Sinoway are well-positioned to thrive in the evolving landscape.

Metal Drop Forging: A Vital Process for Modern Manufacturing

Metal drop forging remains an indispensable process for producing high-strength, reliable components. As industries demand lighter, stronger, and more complex parts, the role of advanced forging techniques will only grow. Sinoway’s commitment to innovation, quality, and customer satisfaction ensures we remain a trusted partner for clients seeking the best in forged and sheet metal solutions.

Conclusion: Forging Ahead with Sinoway

The future of metal drop forging is defined by innovation, sustainability, and integration with complementary manufacturing processes like sheet metal fabrication. At Sinoway, we are proud to lead the way, delivering cutting-edge solutions that meet the evolving needs of our clients. Whether you require precision-forged components, expert sheet metal work, or a combination of both, Sinoway is your partner for success in the next era of manufacturing.

Contact Sinoway today to learn more about our metal drop forging capabilities and how we can help you stay ahead of the curve.