As a leading sheet metal manufacturer, Sinoway understands the critical role that sheet metal processing plays in aerospace manufacturing. From aircraft components to structural supports, sheet metal processing ensures that aerospace parts are both strong and lightweight—essential for safe, efficient flight. In this article, we’ll explore the importance of sheet metal processing in aerospace, the techniques used, and how Sinoway’s expertise contributes to high-quality, reliable aerospace components.

Why Sheet Metal Processing is Essential in Aerospace Manufacturing

The aerospace industry demands precision, durability, and lightweight construction. Sheet metal processing provides a versatile solution that meets all of these requirements, making it indispensable in creating everything from the aircraft fuselage to intricate support components.

High Precision for Safety and Performance

In aerospace, every component must meet rigorous safety standards. Sheet metal processing allows for exacting precision, ensuring each piece fits within specified tolerances. This precision is crucial for components exposed to extreme pressures and temperatures, as even slight deviations can impact the safety and efficiency of the aircraft.

Lightweight Yet Strong Material

Weight reduction is a priority in aerospace manufacturing. Sheet metal, especially aluminum and titanium alloys, offers an ideal balance of strength and lightness, making it a preferred material for various aircraft components. Using advanced sheet metal processing techniques, Sinoway is able to manufacture lightweight parts without compromising durability.

Key Sheet Metal Processing Techniques in Aerospace

Sinoway employs several sheet metal processing methods to create high-quality, reliable aerospace components. Here are some of the essential techniques that make sheet metal suitable for this demanding industry.

1. Laser Cutting

Laser cutting is a popular technique in aerospace manufacturing due to its precision and speed.

How Laser Cutting Works

Laser cutting uses a high-powered laser to slice through sheet metal, allowing for highly accurate cuts with minimal waste. This method is particularly useful for intricate or complex designs that require precise detailing.

Benefits of Laser Cutting in Aerospace

Laser cutting ensures minimal distortion of the material, which is essential for maintaining the structural integrity of aerospace parts. It also produces clean, burr-free edges, reducing the need for additional finishing processes and ensuring better fit and performance.

2. Bending

Bending is a fundamental process in shaping sheet metal to meet specific design requirements for aerospace components.

How Bending Works

Using a press brake, sheet metal is bent at specific angles to form different shapes and structures. The process requires careful control to prevent material fractures or deformation.

Importance of Bending in Aerospace

In aerospace applications, bending is crucial for forming curved parts and structures that match the aerodynamic contours of the aircraft. Sinoway’s advanced bending technology allows for tight tolerances, ensuring each component maintains structural integrity and fits seamlessly within the larger assembly.

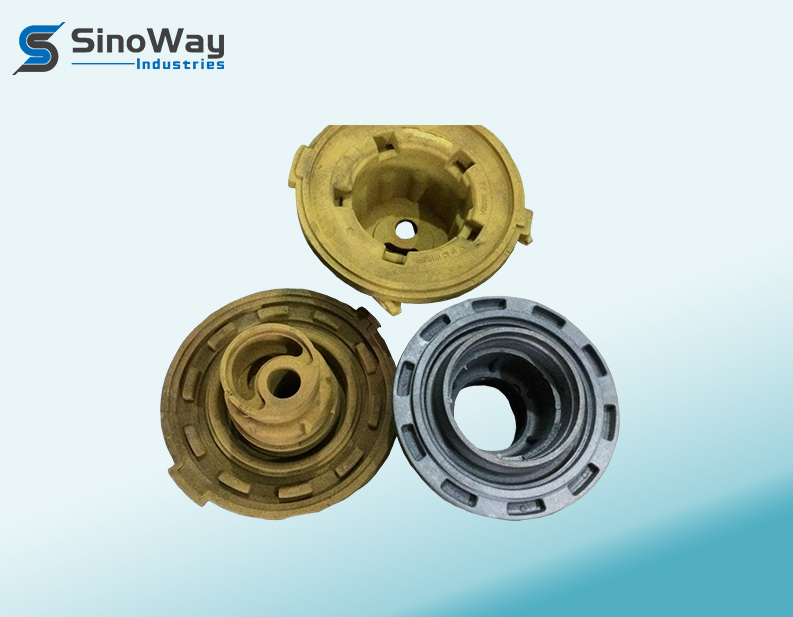

3. Stamping and Forming

Stamping and forming are used to create parts with complex shapes, such as brackets and enclosures, which are essential in aerospace manufacturing.

Stamping and Forming Process

Stamping uses high-pressure machines to press sheet metal into a die, creating the desired shape. This process can be repeated at high speeds, making it efficient for producing large volumes of identical parts.

Benefits in Aerospace

Stamping provides high repeatability, essential for producing uniform components in large quantities. Additionally, forming allows Sinoway to create complex shapes that meet the unique requirements of aerospace applications, enhancing both functionality and aesthetics.

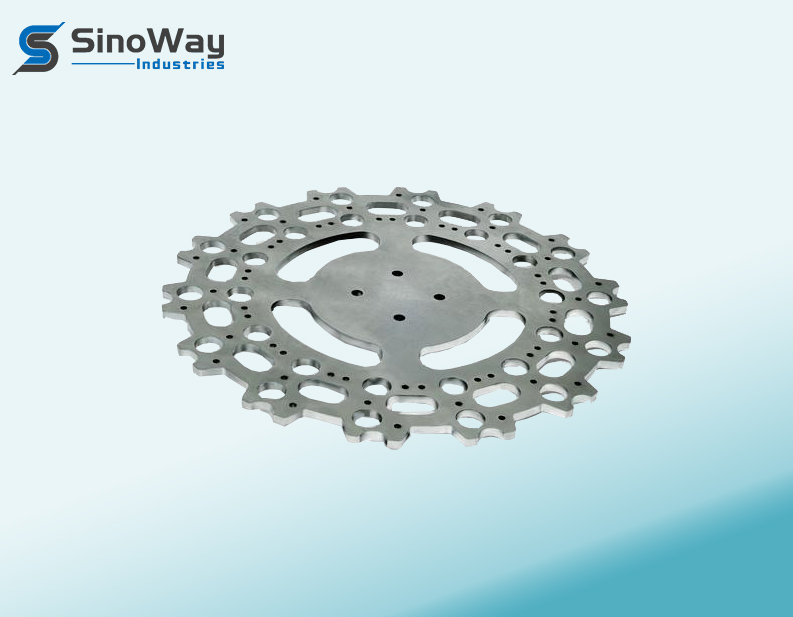

4. CNC Machining

Computer Numerical Control (CNC) machining is a vital process in aerospace sheet metal processing for achieving high precision.

CNC Machining Process

CNC machining involves using computer-controlled tools to cut and shape sheet metal according to exact specifications. This method allows for intricate designs, tight tolerances, and consistent quality.

Why CNC Machining is Critical in Aerospace

In aerospace, CNC machining is indispensable for producing complex, high-precision components with low error margins. At Sinoway, we use CNC machining to meet the industry’s stringent requirements, ensuring each part meets exact specifications for safety and performance.

Materials Used in Aerospace Sheet Metal Processing

Selecting the right materials is as crucial as choosing the processing techniques. Sinoway uses high-quality metals tailored to the demands of the aerospace industry.

Aluminum

Aluminum is widely used in aerospace manufacturing due to its lightweight and corrosion-resistant properties. It’s ideal for components that require high strength-to-weight ratios, such as fuselage panels and structural supports.

Titanium

Titanium is another preferred material due to its strength, low density, and high resistance to extreme temperatures. It is often used in critical components, like engine parts, that are exposed to high stress and temperature fluctuations.

Stainless Steel

Stainless steel is chosen for its excellent corrosion resistance and durability. Although heavier than aluminum, it is commonly used in parts that require additional strength and resistance to wear, such as landing gear components.

Sinoway’s Expertise in Aerospace Sheet Metal Processing

At Sinoway, we understand the unique requirements of aerospace manufacturing and are committed to delivering high-quality sheet metal components that meet strict industry standards. Here’s how we ensure excellence in every aspect of our sheet metal processing for aerospace.

Quality Control and Inspection

Sinoway implements a stringent quality control process at every production stage. Our quality assurance team conducts detailed inspections and tests, ensuring each component meets the exact specifications and safety standards required by the aerospace industry.

Customization and Flexibility

Aerospace manufacturing often involves custom parts tailored to specific aircraft models or functions. Sinoway offers customized sheet metal processing services, allowing clients to choose the materials, designs, and finishes that best fit their needs.

Advanced Technology and Equipment

Our state-of-the-art equipment, including CNC machines, laser cutters, and advanced bending tools, allows us to produce complex, high-precision components. With these resources, we deliver consistent quality and accuracy in every part we manufacture.

Commitment to Sustainability

As an environmentally conscious company, Sinoway prioritizes sustainable practices in sheet metal processing. We reduce waste by using efficient cutting techniques and ensure responsible sourcing of materials, aligning our practices with industry trends toward eco-friendly manufacturing.

Applications of Sheet Metal Processing in Aerospace Manufacturing

Sheet metal processing has a broad range of applications in the aerospace industry, impacting various critical components.

Aircraft Fuselage and Wings

The fuselage and wings require sheet metal parts that are lightweight yet durable. Using techniques like laser cutting and bending, Sinoway produces these essential parts with precision, ensuring they meet aerodynamic requirements and maintain the aircraft’s structural integrity.

Interior Components

Sheet metal processing is also essential for creating interior components such as seat frames, overhead compartments, and storage units. These parts must be both lightweight and durable to meet the stringent safety and comfort standards of passenger aircraft.

Engine and Landing Gear Components

High-strength materials like titanium and stainless steel are essential for engine and landing gear parts, which experience high stress and temperature extremes. CNC machining and stamping are commonly used to create these high-precision components, ensuring reliability and durability.

The Future of Sheet Metal Processing in Aerospace

As the aerospace industry evolves, so do the requirements and technologies associated with sheet metal processing. At Sinoway, we stay ahead by adopting the latest advancements in automation, AI-driven precision, and eco-friendly practices.

Automation and Smart Manufacturing

With the integration of automated machinery and smart manufacturing techniques, Sinoway improves efficiency and consistency in producing high-precision aerospace components. Automation minimizes human error and enhances production speed, allowing us to meet the growing demands of the aerospace industry.

Lightweight and Advanced Materials

In response to the aerospace industry’s continuous pursuit of lightweight materials, we are exploring advanced alloys and composites that provide the necessary strength without adding weight. These materials will likely play a significant role in future aerospace designs, and Sinoway is prepared to integrate them into our manufacturing processes.

Conclusion

Sheet metal processing is at the core of aerospace manufacturing, enabling the production of precise, lightweight, and durable components that are essential for safe and efficient aircraft. As a trusted sheet metal manufacturer, Sinoway is dedicated to delivering top-quality, high-precision parts that meet the stringent requirements of the aerospace industry.

With our expertise in cutting-edge processing techniques, commitment to quality, and focus on innovation, Sinoway is a valuable partner for aerospace manufacturers. Explore our sheet metal processing services today and discover how we can support your next aerospace project with reliable, customized solutions.