When it comes to manufacturing heavy machinery parts, the choice of material and production method is critical. The components need to withstand extreme pressure, high temperatures, and heavy loads while maintaining their structural integrity over time. Among the various options available, steel casting has proven to be the most reliable and efficient solution for producing durable and high-performance heavy machinery parts. In this article, we will explore why steel casting is the preferred choice, with a focus on Sinoway, a leading sheet metal manufacturer that has perfected the art of steel casting for industrial applications.

What is Steel Casting?

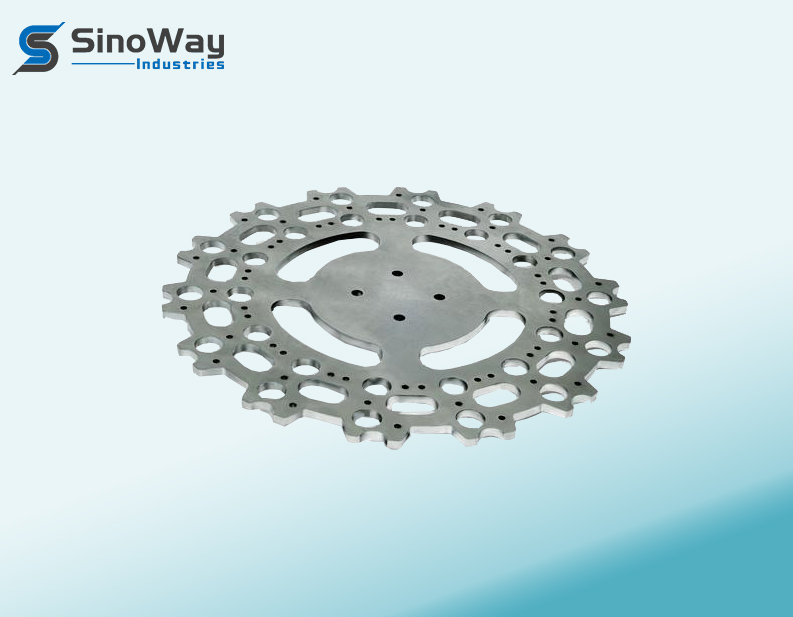

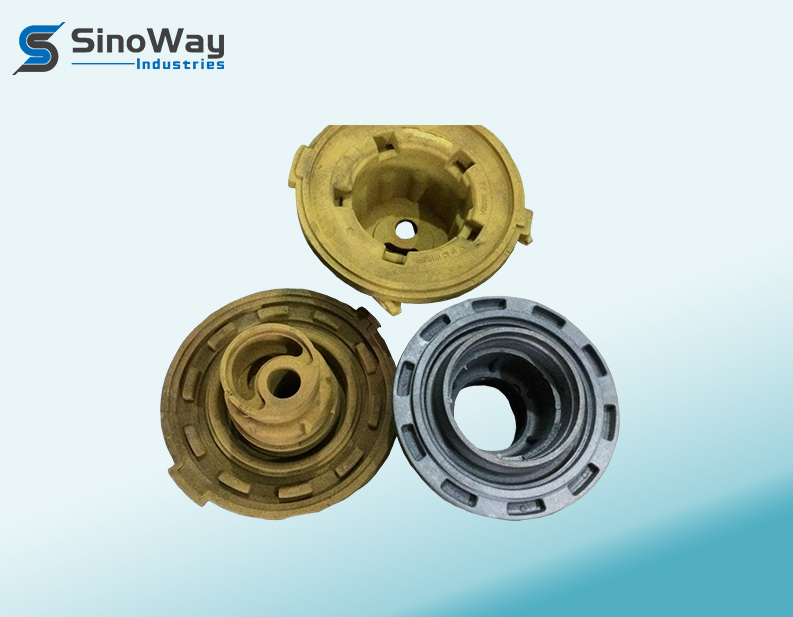

Steel casting is a manufacturing process where molten steel is poured into a mold to create a desired shape. This process is particularly suited for producing complex geometries and heavy-duty components that require exceptional strength and durability. Steel casting offers unmatched mechanical properties, making it an ideal choice for industries such as construction, mining, agriculture, and transportation, where heavy machinery is a critical component of operations.

Sinoway, as an experienced sheet metal manufacturer, has long recognized the advantages of steel casting and has invested heavily in state-of-the-art facilities and advanced techniques. Their expertise enables them to produce high-quality steel castings that meet the stringent demands of modern heavy machinery applications.

Advantages of Steel Casting for Heavy Machinery Parts

1. Superior Strength and Durability

Steel is renowned for its exceptional strength and toughness, making it the material of choice for heavy machinery parts that must endure extreme conditions. Steel castings can withstand high stress and impact without deforming or breaking, ensuring the longevity and reliability of the machinery. Sinoway leverages the inherent properties of steel to produce components that meet or exceed industry standards for strength and durability.

2. Design Flexibility

One of the standout benefits of steel casting is its ability to create complex shapes and intricate designs. This flexibility is crucial for heavy machinery parts, which often have unique geometries to perform specific functions. Sinoway’s advanced casting techniques allow for the production of highly customized components, ensuring that each part fits seamlessly into the machinery and operates efficiently.

3. Cost-Effectiveness

While the initial cost of steel casting may be higher than other manufacturing methods, its long-term benefits make it a cost-effective solution. Steel castings require minimal maintenance and have a longer lifespan, reducing the need for frequent replacements. Additionally, Sinoway’s efficient production processes help to minimize waste and optimize material usage, further lowering costs for their clients.

4. Resistance to Wear and Corrosion

Heavy machinery parts are often exposed to harsh environments, including abrasive materials, moisture, and chemicals. Steel castings are highly resistant to wear and corrosion, ensuring that the components maintain their performance even under challenging conditions. Sinoway employs advanced heat treatment and surface finishing techniques to enhance the resistance of their steel castings, making them ideal for demanding industrial applications.

5. High Load-Bearing Capacity

Heavy machinery parts must be capable of supporting substantial loads without compromising their structural integrity. Steel castings excel in this regard, offering exceptional load-bearing capacity that ensures the safe and efficient operation of the machinery. Sinoway’s rigorous quality control measures guarantee that their castings meet the highest standards for load-bearing performance.

Sinoway’s Expertise in Steel Casting

As a leading sheet metal manufacturer, Sinoway has established itself as a trusted partner for industries requiring high-quality steel castings. Their commitment to innovation, quality, and customer satisfaction sets them apart in the competitive manufacturing landscape. Here are some key aspects of Sinoway’s expertise in steel casting:

Advanced Manufacturing Facilities

Sinoway’s state-of-the-art facilities are equipped with the latest technology for steel casting, including precision molding, automated pouring systems, and advanced heat treatment equipment. These capabilities enable them to produce castings with exceptional accuracy and consistency, meeting the diverse needs of their clients.

Skilled Workforce

Sinoway’s team of skilled engineers, technicians, and craftsmen bring years of experience and expertise to every project. Their deep understanding of steel casting processes ensures that each component is manufactured to exact specifications, delivering superior performance and reliability.

Comprehensive Quality Control

Quality is a top priority for Sinoway. They implement rigorous quality control measures at every stage of the production process, from material selection to final inspection. This commitment to quality ensures that their steel castings meet or exceed industry standards, providing clients with peace of mind and confidence in their products.

Customized Solutions

Recognizing that every client has unique requirements, Sinoway offers fully customized steel casting solutions. Their collaborative approach involves working closely with clients to understand their needs and develop tailored solutions that deliver optimal performance and value.

Applications of Steel Castings in Heavy Machinery

Steel castings are used in a wide range of heavy machinery applications, including:

- Construction Equipment: Components such as excavator arms, bulldozer blades, and crane hooks are commonly made from steel castings to ensure strength and durability.

- Mining Machinery: Steel castings are used for parts like crusher jaws, grinding mills, and conveyor components that must withstand abrasive materials and heavy loads.

- Agricultural Equipment: Plowshares, harvester blades, and tractor components benefit from the wear resistance and toughness of steel castings.

- Transportation: Steel castings are used in railways, trucks, and marine vessels for components that require high load-bearing capacity and resistance to corrosion.

Environmental Benefits of Steel Casting

In addition to its performance advantages, steel casting offers significant environmental benefits. Steel is a recyclable material, and the casting process generates minimal waste compared to other manufacturing methods. Sinoway is committed to sustainable practices and continuously seeks ways to reduce their environmental footprint, making steel casting an eco-friendly choice for heavy machinery parts.

Conclusion

Steel casting is undoubtedly the best solution for heavy machinery parts, offering unparalleled strength, durability, and design flexibility. Sinoway’s expertise as a sheet metal manufacturer ensures that their steel castings meet the highest standards of quality and performance, making them a trusted partner for industries worldwide. By choosing steel casting and partnering with Sinoway, businesses can achieve greater efficiency, reliability, and cost-effectiveness in their heavy machinery operations.

Whether you need components for construction, mining, agriculture, or transportation, Sinoway’s steel casting solutions are designed to meet your specific needs and exceed your expectations. Contact Sinoway today to learn more about their innovative steel casting services and how they can help you achieve your manufacturing goals.